HEAT TREATMENT

irina88w/iStock / Getty Images Plus via Getty Images

Heat Treating the Kitchen

Reed Miller, Editor

This month, we take a look at some of the common things found in our kitchens to see how they are heat treated.

Cast-Iron Cookware

Cast-iron cookware is an iconic part of kitchens and cooking. After a lull in popularity, cast iron is resuming its place in our kitchens because it offers several benefits not available with other cookware options. Before we discuss this in more depth, let’s look at what it takes to get that frying pan into your hot little hands.

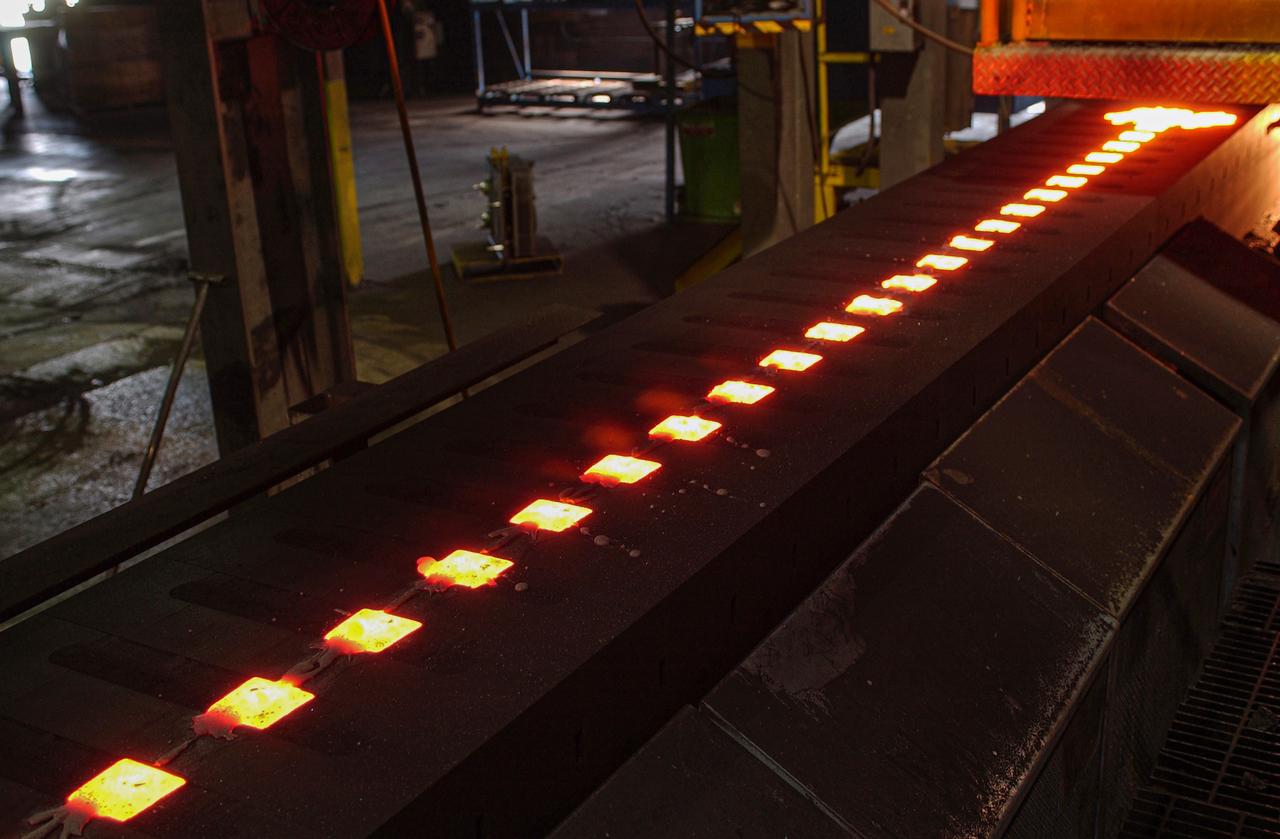

Much like its steel cousin, cast iron begins life as scrap. The scrap is given a premelt thermal treatment at 600°F to remove any residual oil or water. A charge of pig iron, steel scrap and recycled cast iron is melted at 2800°F in an electric induction furnace with a bath size of about 3 tons. It takes about 15 minutes to heat the scrap to liquid, at which time the bath is chemically sampled. After final chemical additions are made – usually silicon is added at this time – the bath is poured and slagged off using vermiculite.

A mold machine makes impression molds in green sand, which is sand, clay and water, using steel tooling. One U.S. manufacturer makes over 120 different castings for its wide product range. This includes 20 different sizes and shapes of skillets, 14 different Dutch ovens, griddles, grill pans, platters and more.

The iron is cast at 2500°F, which is critical for good-quality castings. If it is hotter, it will penetrate the sand, creating a poor surface quality. If it is too cold, it will not adhere to the sand, creating an incomplete casting. Either condition could result in scrapping the product. The casting process is programmed for a specific configuration, and a preprogrammed amount of metal is injected into each mold. Depending on the configuration, a total of 400-1,600 pieces/hour can be cast in the sand-mold machine.

Reed Miller, Industrial Heating

SergeyChayko/iStock / Getty Images Plus via Getty Images

After casting, the cookware moves along a vibrating conveyor for about 40 minutes to remove the sand, which is recycled. The pots and pans are then tumbled with pieces of cast iron to remove the rough edges. Flashing can also be hand ground if it is excessive. This is followed by a shot blast, and the final preparation is a river-rock bath. At this point, the cast iron is ready to be seasoned.

Historically, seasoning was done after the cookware was purchased. It also occurs naturally after regular use. To make today’s cast-iron cookware more user-friendly, however, manufacturers now season the cookware by electrostatically spraying it with vegetable oil. It is then baked in an oven to produce an adherent black coating.

Why cast iron, and why is it seeing a resurgence in popularity? Cast-iron cookware has been mass-produced since Civil War days. A company in Pennsylvania that began by making door hinges became world reknown for its fine cast-iron products. Unfortunately, in the 1940s, this company went out of business because of the influx of alternative cookware – aluminum, in particular. Cast-iron cookware experienced a season where it fell from favor because of these “improvements.” Now, what’s old is new again.

Included among the reasons for this resurgence is the nonstick nature of the seasoned finish. Less oil can be used in cooking, resulting in a lower-calorie dish. Cast iron can withstand very high cooking temperatures, which makes it a common choice for searing or frying. Its excellent heat diffusion and retention makes it a good choice for long-cooking recipes such as stews. Additionally, small amounts of iron can leach into the food, which is typically a benefit. Aluminum cookware has long struggled with the potentially negative leaching of aluminum metal into the food.

A regional influence is also seen in cast-iron cookware’s popularity. It is reported that Dutch-oven cooking is quite popular in the plains states and Utah. Maybe it’s time to dust off your old cast-iron skillet or pick up a new one for that budding chef.

Refrigerator Hinge

What could be more common than the household refrigerator? It is the most-used appliance in America with almost 100% of homes having one. Can you believe that at the start of the 20th century, about half of the households in the U.S. relied on melting ice – in an icebox – to keep food cold? The icebox was used for about 150 years until the invention of the mechanical refrigerator in the late 1800s.

The first documentation of artificial refrigeration occurred at the University of Glasgow in 1748. William Cullen’s work relied on the vapor-compression refrigeration process explained by Michael Faraday. While different processes were investigated until the late 19th century, Carl von Linde is widely considered the father of the modern refrigerator. His invention of a continuous process of liquefying gases in large quantities formed a basis for today’s refrigeration technology.

Based on early patented work from France, General Electric manufactured the first refrigerating machine marketed by the Johns Manville Company. The first unit was sold in 1911 for about $1,000 – twice the cost of an automobile that year. GE developed and marketed the “Monitor-Top” refrigerator in 1927. It was the first to see widespread usage with over 1 million units being produced. Many of these units are still functioning today. Technological developments continued throughout the 20th century with the incorporation of a frozen-food compartment, automatic defrosting and automatic icemakers to name just a few.

Reed Miller, Industrial Heating

Most common household refrigerators make use of the thermodynamic vapor-compression cycle. A circulating refrigerant (such as Freon) enters the compressor as a vapor at its boiling point. This vapor is then condensed into a liquid at its boiling point. The liquid refrigerant then passes through an expansion valve where the pressure quickly decreases, resulting in the flash evaporation and auto-refrigeration of a portion of the liquid. This refrigerant requires kinetic energy, which is extracted in the form of heat from the food compartment via the evaporator.

No doubt several components of a modern refrigerator rely on thermal treatment for proper functioning. Items like springs come to mind. One that you may not think about is the lower door hinge. Why the lower door hinge and not the upper? The lower hinge carries all of the weight. Today’s refrigerator doors contain add-ons such as water dispensers and are designed to hold large items like gallons of milk. And that says nothing about the 5-year-old who enjoys hanging from the door while it swings open.

A supplier to a refrigerator maker like GE typically manufactures the lower hinge. These hinges are made from 1050 carbon steel and are through-hardened, quenched and tempered to the ideal hardness. A commercial heat treater is usually the one to perform this operation in continuous atmosphere furnaces.

An endothermic atmosphere is generated that is neutral to the carbon in the hinge material. The post-hardening oil quench is followed by a wash, and the part is also coated on high-end refrigerators.

It is often remarkable to look at quantities of items such as this. At a single commercial heat treater in Ohio, approximately 275,000 ½-pound hinges are heat treated every month. That’s 3.3 million every year for the number crunchers out there.

The Kitchen Sink

We don’t want it to be said that we discussed “everything but the kitchen sink.” So, here you go.

While stainless steel kitchen sinks seem to be ubiquitous, they have only existed for the past 85 years or so (about as long as Industrial Heating!). Kitchen sinks made from other materials (e.g., stone) trace back about 150 years. Even enameled cast-iron sinks were not used before the 1890s. Prior to that and the availability of running water and sewage, a bowl or bucket was used inside a dry sink, which was a metal trough built into a wooden cabinet.

Although stainless steels – alloys of iron, chrome and nickel – had been studied as early as 1821, the process to make the steel corrosion resistant was not identified until 1909. The key was finding a way to eliminate the carbon in the steel, which would combine with the chromium and reduce the corrosion resistance.

Kitchen sinks formed from stainless steel are still a popular choice because they are lightweight, attractive, easy to clean and won’t stain or rust. Old kitchen sinks and other stainless material are recycled into stainless by melting in an electric furnace. The molten metal is transferred to an AOD (Argon-Oxygen-Decarburization) vessel for refining and blowing out the carbon. Without changing the activity of the oxygen by using argon, chromium would be oxidized into the slag during this process. The AOD allows the carbon to be preferentially oxidized while retaining most of the chromium. The balance is reduced back from the AOD slag at the deoxidation stage of the melt process.

The process for manufacturing a sink begins by cutting the steel coil into blanks. Under a 1,000-ton press, a punch stretches the blank into a bowl form, which also work-hardens the steel. Lubricant is brushed into the bowl, and it is stretched a second time, further hardening it. Next, a drain hole and lip is formed in the bottom of the bowl. A belt sander is then used inside the bowl to give it a brushed appearance.

For a double-bowl sink, two of these bowls are butted together and electrode welded. A roller flattens the weld followed by a sander to smooth it. The rim recesses are then formed, and it is trimmed. Next, holes are punched for the faucets and a sprayer or soap dispenser. The bowl is then completely brushed to give it a fine finish. This process takes about 25 minutes, and it requires a skilled operator. The manufacturer’s name or logo is then embossed into the bowl followed by coating the bottom with heavy latex, which helps to deaden the sound. The entire sink manufacturing process takes about 2.5 hours.

Vac1/iStock / Getty Images Plus via Getty Images

The refined steel can be cast in a variety of ways, but for the manufacture of sink-bowl material, it is typically cast into slabs and rolled into hot-band coil. This is followed by a hot-acid wash, known as the annealing and pickling process. It will be cold rolled to the final gauge in specialized mills called “Z” mills for the inventor, Tadeusz Sendzimer. The Z mill is able to roll stainless to very thin gauges while maintaining uniform thickness across a wide strip. Sometimes the cold-rolled coil will need to be re-annealed to be able to roll it to very thin gauges.

In-process anneals for stainless are required because it work-hardens when rolled. The annealing time and temperature are critical to forming a good kitchen sink from the material. If the annealing line stops beyond the time allowed by the strip accumulator, the line stop could overheat a portion of the steel, causing grain growth. When drawn into a sink, this will result in an “orange-peeled” condition, which is aesthetically unpleasant and may also affect drawability. A full anneal also helps the sink manufacturer because the bowl will not work-harden as quickly during drawing.

Of the three basic types of stainless – austenitic, ferritic and martensitic – austenitic stainless is used for sink bowls. Typically, a special alloy variation, usually indicating “SBQ” for sink-bowl quality, is used to enhance the drawability. Drawability was one of the limitations in the early use of stainless for sink bowls. Deeper bowls of the time were probably welded versus drawn.

We hope you have enjoyed this look at all of the thermal processes involved in common kitchen products. If you would like to read more about the thermal processing of everyday items, pick up a copy of Everyday Metallurgy in our online bookstore.

Editor Reed Miller has been providing technical resources to the Industrial Heating community for more than 15 years.

INDUSTRIALHEATING.COM | 90th ANNIVERSARY | SEPTEMBER 2021

SEPT 2021

SEPTEMBER 2021