Heat & Corrosion Resistant Materials/Composites

gorodenkoff/iStock / Getty Images Plus via Getty Images

Precipitation-Hardenable Steel: Annealed or Aged?

Marc Glasser – Rolled Alloys; Temperance, Mich.

As a customer technical-support metallurgist, one question that customers ask over and over is whether their precipitation-hardenable steel is annealed or aged. This question is apropos to A286, 718, 17-4, 15-5, 13-8 and other precipitation-hardenable alloys.

Any and all of these precipitation-hardenable (PH) steels can either be in the solution-treated condition, which implies and means that they are hardenable but not yet age hardened, or they can be solution treated and precipitation hardened (also referred to as age hardened). For steels in the 17-4 category, the material is designated as in the Hxxxx condition, with the “x”s being the temperature at which age hardening occurs.

The test reports and mill certifications can be very difficult to decipher, particularly for 718. The reason for this is that all specifications require PH material to be tested in the aged condition. When specifications require solution-treated and precipitation-hardened (aged) material, testing is required both before and after aging and all material is supplied as aged material.

When specifications require solution-treated material and precipitation hardenable, testing is required for solution-treated material, which is referred to as condition A. This material is not supplied in the aged or hardened condition. Instead, a representative sample from each heat in a heat-treating batch has to be aged and tested in the same way that fully aged material must be tested. This testing of an aged sample from each lot is commonly referred to as capability testing, and it is performed to demonstrate that material is capable of being aged and meeting all required properties of fully aged materials. The actual material has not yet been aged; it is still in the solution-treated or solution-annealed condition. Only a small representative sample has been aged and tested in the aged (hardened) condition.

davit85/Stock / Getty Images Plus via Getty Images

How does a machine shop or fabricator determine what condition the material he is working on is in? The answers can be found in the mill certifications and test reports with a little understanding on how to interpret. There are some telltale indicators. One just needs to know how to find them.

In the case of 17-4 and other alloys of this class, the first indication is in the first section often labeled “Material Condition,” perhaps with the added wording “as shipped.” The certification will often specifically state condition A. In the event that the actual material has been aged, the test report will indicate that the material is in the Hxxxx condition, where xxxx is the actual aging temperature. For example, condition A material will be indicated by a designation of condition A, solution treated or solution annealed. Aged material will show a condition of H1150 (or a different aging temperature).

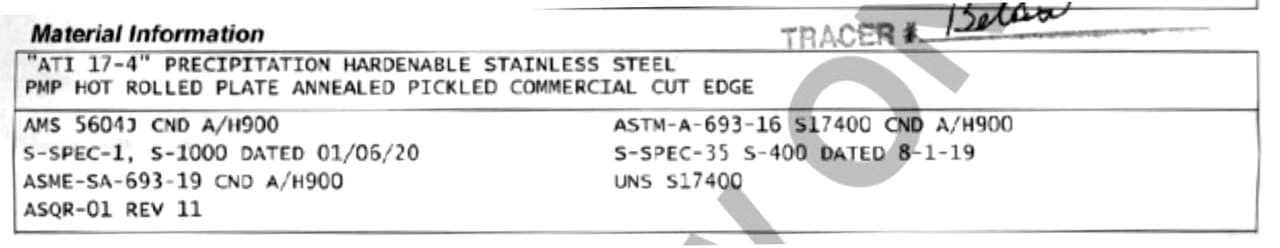

Other mill reports will state that the material condition is hot rolled (or cold rolled), annealed and pickled. The “annealed” should be taken to mean that it is in condition A. ASTM A941,[1] which is a definitions specification, defines the terms solution annealing and solution treating as synonyms for annealing. Other mill certifications may show mechanical testing on material as-shipped and as-tested. In this case, one should interpret this to mean that the material is solution treated only. Examples of test reports showing material in condition A or solution treated are shown in Appendix A. Examples of mill test reports that indicate that 17-4 material is age hardened are shown in Appendix B.

Material in condition A per line 2 – Hot-rolled plate, annealed, pickled and commercial cut edge. Also, AMS 5604[3] specification title includes “solution heat treated, precipitation hardenable.”

Appendix A: Examples of 17-4 Condition A as found in Mill Certification

In this second mill certificate, the only surefire way of determining the condition is from the referenced specification: AMS 5604G, whose title once again specifically states “solution heat treated, precipitation hardenable.”

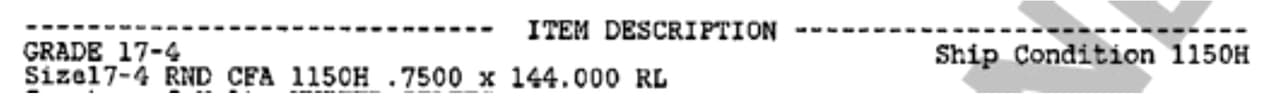

Appendix B: Examples of 17-4 Age-Hardened Material as shown in Mill Certification

This excerpt from the mill certification clearly shows 1150H and ship condition as 1150H. These are clear statements that the material has been aged to the H1150 condition.

Test reports for 718 can be even more challenging to decipher. A review of mill certificates from various sources have different wording to indicate the as-shipped condition is solution treated, including:

Hot rolled, annealed and pickled

Hot rolled, descaled and pickled

Condition M – mill thermal treatment 1750°F (actual time) and water quenched

Examples of 718 mill test reports indicating as-shipped condition are shown in Appendix C.

When material is certified to an AMS specification, the specification itself will include the condition of the shipped material in the title of the description. For example, the title of AMS 5662[2] includes the words solution heat treated and precipitation hardenable. The word hardenable implies, and should be taken to mean, that the material has not yet been hardened. Rather, it is capable of being hardened.

Within the text of the specification is a subsection labeled response to heat treatment. This section requires a sample to be age hardened and tested as age hardened to demonstrate that the heat is capable of meeting the age-hardenend properties specified. Once again, only the sample has been age hardened. The rest of the heat is still in the solution-treated condition. Examples of 718 mill test reports indicating the as-shipped condition are shown in Appendix C.

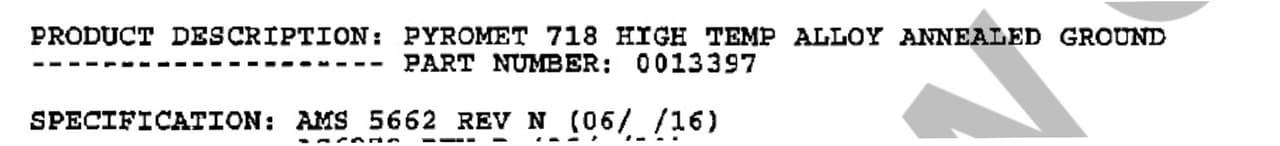

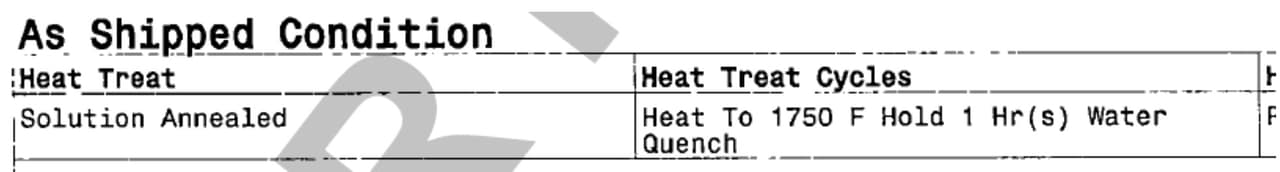

Appendix C: Examples of 718 in Condition A

“718 annealed” and “AMS 5662” clearly show that the material is in condition A. The title of AMS 5662 includes solution heat treated, precipitation-hardenable. The word hardenable should be taken to mean that the as-shipped material has not yet been hardened.

The material condition is explicitly stated to be solution annealed in this particular mill certification, and the next column elucidates the heat treatment.

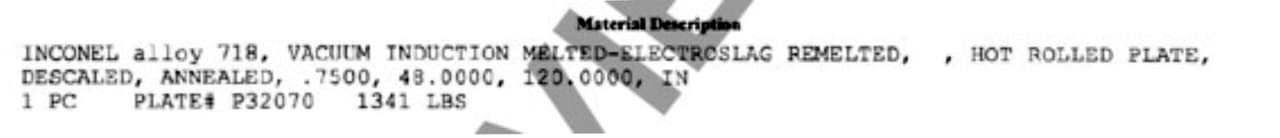

It is explicitly stated to be hot-rolled plate, descaled and annealed in this mill certification. The annealed by definition means that the material has been solution treated.

AMS 5663[3] is for age- or precipitation-hardened 718 materials. It is almost identical to AMS 5662 except that the title states solution heat treated and precipitation hardened. The difference is that 5662 uses the word hardenable, implying not yet hardened, and 5663 uses the word hardened, which is explicit – the material has already been hardened.

AMS specifications are excellent references that will clarify not only the condition of the material but what testing is required. In the case of the PH materials, the specifications will clarify which testing is to be performed on the as-shipped, solution heat-treated material and which testing is required to prove its response to heat treatment (capability).

The solution heat-treated material must be tested for hardness, average grain size and microstructure. Acceptance criteria are specified as well – either descriptively, quantitatively or by reference to another specification. Response to heat treatment must be tested for room-temperature tensile properties, for hot tensile properties at 1200°F, and for hardness and stress-rupture properties at 1200°F. There are also required properties of response to heat treatment after re-solution treatment and precipitation heat treatment.

When test reports list applicable specifications and an AMS specification is included in this list, a quick look at the title of the AMS specification is the easiest way to determine the condition of the as-shipped material.

For more information: Contact Marc Glasser at Rolled Alloys, 125 West Sterns Road, Temperance, MI; tel: 800-521-0332, e-mail: metallurgical-help@rolledalloys.com; web: www.rolledalloys.com.

1. ASTM A941. Standard Terminology Relating to Steel, Stainless Steel, Related Alloys, and Ferroalloys. ASTM International. Conshohocken, PA. 2018

2. AMS 5662. Aerospace Material Specification Nickel Alloy, Corrosion and Heat-Resistant Bars, Forgings, and Rings 52.5Ni-19Cr-3.0M0-5.1Cb(Nb)-0.90Ti-0.50Al-18Fe Consumable Electrode or Vacuum Induction Melted 1775°F (968°C) Solution Heat Treated Precipitation Hardenable. SAE International. Warrendale, PA. 2016

3. AMS 5663. Aerospace Material Specification Nickel Alloy, Corrosion and Heat-Resistant Bars, Forgings, and Rings 52.5Ni-19Cr-3.0M0-5.1Cb(Nb)-0.90Ti-0.50Al-18Fe Consumable Electrode or Vacuum Induction Melted 1775°F (968°C) Solution and Precipitation Heat Treated. SAE International. Warrendale, PA. 2016

INDUSTRIALHEATING.COM | 90th ANNIVERSARY | SEPTEMBER 2021

SEPT 2021

SEPTEMBER 2021