Screwdriving and Riveting

Labor shortages are driving new demand for automation.

Options for Screwfeeding

At Dräxlmaier, screwdriving tools are fitted with permanent infrared trackers. Photo courtesy Desoutter

Infrared system locates position of fastening tools in real time with no latency.

Battery Manufacturing

New Technology Error-Proofs

Thomas Preuss // Contributing Writer

Dräxlmaier is among the top automotive suppliers in Europe. Its customers include Porsche, Audi, Volkswagen, Daimler and BMW.

At the company’s factory in Sachsenheim, Germany, workers assemble 800-volt battery packs for electric vehicles. Each pack requires hundreds of screws, which are installed both manually and robotically. Every screw connection is classified as “category A” according to the German manufacturing standard VDI/VDE 2862 sheet 1, which governs threaded fasteners and the tools for installing them. “Category A” joints require the highest safety standards.

Every screw must be successfully installed in the right location with the correct torque and angle parameters. Each time a screw is installed, the results are automatically documented to provide evidence of the required quality.

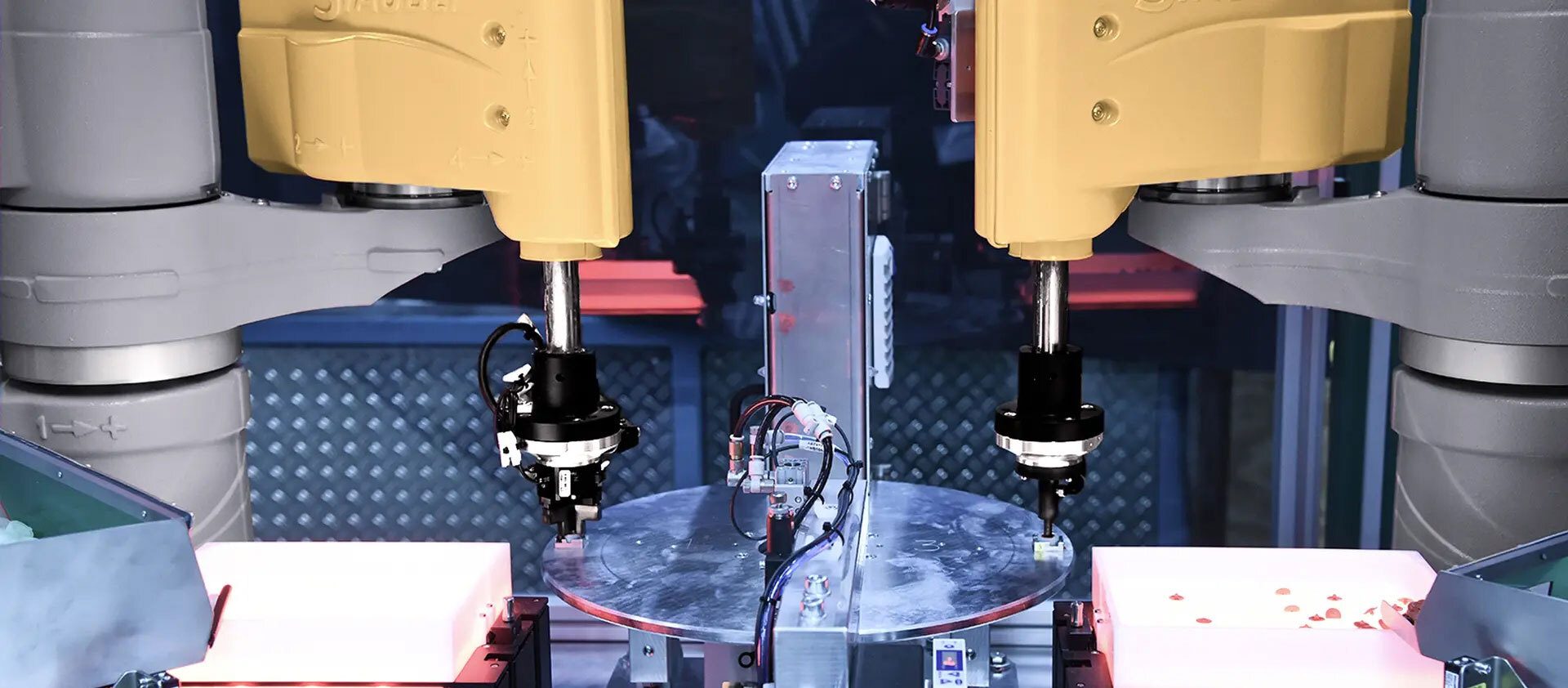

At the Sachsenheim plant, many processes for battery assembly are automated. Robots have taken over the task of inserting screws and are programmed to identify each fastening location. Although the robotic screwdriving process is fast and accurate, some insertions invariably fail. For example, a screw might occasionally slip off the bit, or the driver might not be perfectly aligned with a hole. These faulty insertions must be reworked manually.

Whether automated or manual, the same quality requirements apply.

Each battery pack requires hundreds of screws, which are installed both manually and robotically. Photo courtesy Desoutter

The Challenge

Because installing each fastener in the right spot is just as important as meeting torque and angle requirements, Dräxlmaier engineers needed a way to determine the exact position of the fastening tool during assembly without restricting the movement of workers.

Engineers wanted a real-time location system that would only activate a screwdriver if it was located over the correct fastener. And, every rework step had to be monitored and documented.

Engineers also wanted a user-friendly system that could be standardized at all of the company’s manufacturing sites worldwide. (The company employs some 74,000 people globally.)

The Nexonar system from Desoutter solved the problem. Nexonar uses infrared technology to accurately locate the position of any asset within 1 millimeter in real-time and with zero latency. A small, infrared target is attached to whatever object, such as a fastening tool, that needs to be tracked and located. A camera system above the workstation detects infrared light emanating from the target and uses triangulation to determine its position in space. The system is product agnostic and works with a variety of tool brands.

Each target can be located with six degrees of freedom by a single camera. With many cameras, a variety of workstations can be monitored. Generally, one or two cameras are sufficient for an assembly station. With a sampling frequency of 163 hertz, even fast-moving objects can be located.

Up to 16 trackers can be captured with a single camera in a range of approximately 8.8 by 4.8 meters. One camera with wide angle covers a working area with a depth of 0.2 to 5.5 meters.

The Nexonar system can be paired with a manufacturing execution system or digital work instruction software to guide operators during assembly and error-proof production. This ensures that an assembly cannot leave a station unless every fastener has been installed correctly. It’s also useful if fasteners must be installed in a particular sequence, or if torque and angle settings change from one location to another.

For additional guidance, the Nexonar system can be paired with an augmented reality system to visually show workers—directly on the assembly—which fastening location to address next.

The system can be used with more than just fastening tools. For example, transmitters can be attached to an assembler’s hands to ensure accurate part picking, placement and fulfillment in kitting operations.

Flexibility is a key advantage of the system. “We can react to changes in workstation configuration in a straightforward way. The Nexonar system is flexible and can be adapted and expanded due to its modularity,” says Maximilian Wien, sales manager at Desoutter. “This also allows us to respond to specific customer requirements and develop individually tailored solutions.”

At Dräxlmaier, screwdriving tools are fitted with permanent infrared trackers. Trackers are also attached to each of the battery packs so their exact position on the line is also transmitted. A well-aligned cluster of cameras ensures that all fastening locations can be accurately detected.

Dräxlmaier engineers like the Nexonar system’s high degree of measuring accuracy, unrestricted ergonomics, and straightforward commissioning. The system also quickly achieved a high level of acceptance among employees.

“We were very positively surprised that, even when we were initially testing the system, everything worked flawlessly right from the start,” says Christian Grötzinger, product manager at Dräxlmaier.

Since implementing Nexonar, product quality and employee satisfaction have risen significantly. Photo courtesy Dräxlmaier

Assembling Battery Packs

Battery pack assemblies are transported along the assembly line by automated guided vehicles (AGVs).

In the first step, battery cells are inserted into frames by robots and fixed automatically. This is followed by the placement of bus bars and a few manual assembly steps. While some assembly steps are always carried out, others are only needed under certain conditions. Dräxlmaier can monitor and control fastening in any position.

The work steps are now monitored by Nexonar’s infrared positioning technology. Several infrared cameras and trackers work together on the tools and batteries. For horizontal screw locations, the tools are equipped with several trackers. This ensures that a tool tracker can be identified in the camera’s field of view at any time, and allows assemblers to move freely around the room with their tools. Position control means that the tool will only start when it is at the specified fastening location.

The highest demands on the system occur when the bus bars are positioned and fastened. The distance from one screw head center to the next is only 16 millimeters.

To ensure accurate location of the battery pack assemblies on the line, the AGVs are equipped with reference trackers. The purpose of these is to precisely measure the position of the battery storage unit. The workstations themselves are equipped with several cameras which ensure that the tools and the position of the product can always be identified.

To ensure accuracy, trackers are installed on the tools themselves. These measures guarantee that employees are always at the correct fastening location, even if there is another screw a few millimeters away.

If a fastening error is detected during the automated assembly process, that step will need to be reworked manually. This can mean loosening a screw that has already been tightly fitted. Since tightened screws are difficult to distinguish from each other, the Nexonar system verifies that only the relevant screws are removed, in a controlled manner, and reinstalled correctly. Nexonar ensures that assemblers carry out the disassembly and reassembly in the right place.

Multiple Benefits

Since implementing Nexonar, product quality and employee satisfaction have risen significantly.

Employees can install screws freely and flexibly, without the need for a fixed multiaxis positioning system. Each screw is placed precisely in position. Both at the initial assembly stage and at the reworking station. And, each screw insertion is documented for complete traceability.

“With Nexonar, we are able to ensure that all screws are installed according to specification,” says Grötzinger.

For more information on assembly tools, visit https://us.desouttertools.com.

Dräxlmaier battery factory in Sachsenheim, Germany, is highly automated. Photo courtesy Dräxlmaier

ASSEMBLY ONLINE

For more information on fastening tools and real-time location systems, visit www.assemblymag.com to read these articles: