Supplier's

Marketplace

Charles Ross & Son Co.

710 Old Willets Path, Hauppauge, N.Y. 11788; 800/243-7677; www.mixers.com.

Ross VersaMix triple shaft mixers

Charles Ross & Son Co. offers its ROSS VersaMix triple shaft mixer, which handles challenging mixing applications requiring efficient powder dispersion and critical homogenization of medium to high viscosity slurries, pastes, gels, creams and suspensions, the company says. The VMC-40 (pictured above) is designed for full vacuum operation and includes a three-wing anchor agitator with Teflon blades scraping the sidewalls and bottom surfaces of the vessel. The VMC-40 also features a high shear mixer with solids/liquid injection manifold (SLIM) technology, which draws solids sub-surface for virtually instantaneous wet-out. A high speed disperser allows the mixer to apply shear as the batch increases in viscosity. The highly repeatable mixing process features fine dispersion, deagglomeration, emulsification, temperature control and degassing, which are all accomplished in the VersaMix in a highly repeatable process, it says. The vacuum cover features an explosion-proof tank light, RTD thermoprobe, clean-in-place spray nozzles and a dedicated port for nitrogen purging.

Ardagh Metal Packaging

800/323-3401; www.ardaghmetalpackaging.com.

Ardagh Metal Packaging’s H!GHEND

Ardagh Metal Packaging - Europe recently launched H!GHEND, a new addition to its customization range, which offers customers brand-enhancing creative opportunities. The company explains that the H!GHEND innovation series adds extra value to the can end, making this area of the pack a newly valuable player in overall branding. The versatile technology allows high quality decoration in CMYK colors on the entire shell surface, meaning brands can highlight, customize and differentiate their cans with maximum visual impact, the company says. Not only does H!GHEND color perfectly match specific color branding, customers can explore H!GHEND images to open up a world of graphics possibilities and can use H!GHEND pro to differentiate special editions or collectables, it notes. Additionally, customization is available for small runs and is flexible to brands’ changing needs. For main pack enhancement and brand reinforcement, H!GHEND color offers advanced full-shell printing in solid or transparent color that can be left pure and simple or upgraded with a colored or special tab for color-based branding at every sip, it says.

KeyKeg sustainable packaging for beer

OneCircle, formerly known as Lightweight Containers, offers its sustainable, returnable products for the brewing industry: KeyKeg. The company has partnered with HVB, which was founded in 2018 by Benny Van Heule, to supply Belgian and Dutch breweries with the materials they need to brew and package beer including ingredients, bottles and key caps. With KeyKeg added to their product range, HVB now is a one-stop shopping experience for Belgian brewers, the companies say. The sustainable, returnable KeyKeg contains 86% recyclable material and 39% circular material. The circular design also allows the company to reuse material from empty kegs to make new kegs.

OneCircle

Koperslagersweg 4, 1786 RA Den Helder, The Netherlands; info@lightweight-containers.com; www.lightweight-containers.com.

SIG’s SIGNATURE EVO aspetic cartons

SIG Combibloc Inc. brought to market an innovative full barrier, aluminum-free aseptic carton pack solution: SIGNATURE EVO. Already available for plain white dairy milks, SIGNATURE EVO’s usage extends to a wider portfolio of oxygen-sensitive products such as fruit juices, nectars, flavored milk or plant-based beverages, the company says. SIGNATURE EVO packaging materials are expected to offer a similar carbon footprint reduction to combibloc ECOPLUS, to be confirmed through an independent, critically reviewed, lifecycle assessment, the company says. Like all SIG packs, SIGNATURE EVO is fully recyclable in existing recycling streams. With barrier properties comparable to standard aseptic cartons that include an aluminum foil barrier layer, SIGNATURE EVO packaging materials ensure that even oxygen-sensitive products are protected over long periods of time without the need for refrigeration, it says. SIGNATURE EVO initially will launch in the combiblocMini portion-sized format before being extended to other formats. It is suitable for both oxygen-insensitive products like plain white UHT milk and oxygen-sensitive products like fruit juices, nectars, flavored milk or plant-based beverages, it notes.

SIG Combibloc Inc.

2501 Seaport Drive, Suite 100, Chester, Pa. 19013; 610/546-4200; www.sig.biz.

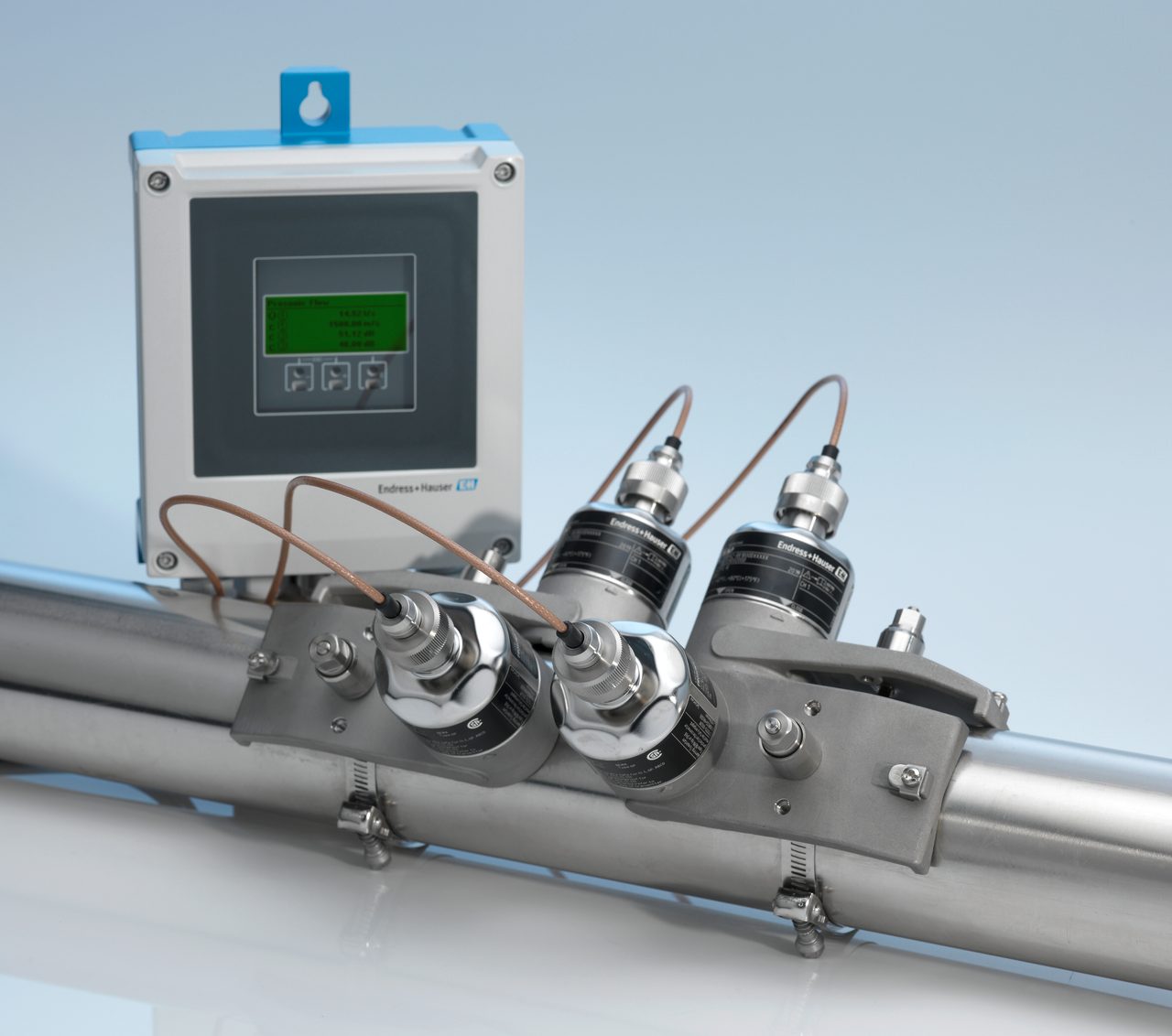

Endress+Hauser clamp-on ultrasonic flowmeter

Endress+Hauser launched its advanced clamp-on flowmeter unit for water, wastewater and other process industry applications. The Proline Prosonic Flow W 400 provides a reliable liquid flow solution with ease of installation and user-friendliness for a variety of liquid measurement applications. The W 400 clamp-on and I 400 insertion unit provides comprehensive process monitoring with long-term cost-efficiency and extensive diagnostics, the company says. The sensors pair with the company’s Proline 400 transmitter to provide a complete flow metering solution. In addition to providing ultrasonic clamp-on instruments for convenient flow measurement, Prosonic Flow W provides reliable instrument data and measurement of process parameters. With an ultrasonic sensor mounted directly on the pipe’s exterior, the flowmeter uses a nonintrusive, clamp-on measurement method that fosters safe measurement of many fluids, independent of their conductivity or other properties. This includes corrosive, abrasive, and toxic fluids, making this flowmeter ideal for monitoring countless processes. The flowmeter’s IP68 Type 6P submergence-rated ultrasonic sensors provide long-term and reliable operation, requiring little maintenance, it says. It also can withstand harsh temperatures from minus 40 degrees Fahrenheit to 266 degrees Fahrenheit.

Endress+Hauser

2350 Endress Place, Greenwood, Ind. 46143; 317/535-7138; www.endress.com.

NGO Energy Vision, New York, published a new report on waste and recycling collection truck fleets. Entitled “The Refuse Revolution,” the report was conducted over a 20-year period and assesses various alternative fuels and new vehicle technologies for reducing greenhouse gas (GHG) emissions and other negative impacts from the more than 180,000 heavy-duty trucks operating on U.S. roadways that consume more than 20% of on-road vehicle fuels, the report states. Of the nine options studied, including biodiesel, fossil and battery electric vehicles, the study found that non-petroleum fuel options such as renewable natural gas (RNG) could cut U.S. methane emissions by 15%, it adds. RNG trucks rated highest in terms of performance, cost, and cutting lifecycle GHG emissions, health-damaging pollutants and more, the report found.

Atlanta-based Graphic Packaging announced that Maggie Bidlingmaier has joined the team as executive vice president (EVP) and president of the Americas business unit, while her predecessor Joe Yost now serves as EVP and president of the International business unit, based in Brussels. In her new role, she is charged with developing superior team dynamics, driving growth of the fiber-based packaging segment and bringing the company’s high-performance culture to the next level. Likewise, Yost is responsible for converting operations outside the Americas, including the company’s businesses in the EMEA, Australia and New Zealand.

Packaging experts and partners at McKinsey, David Feber and Daniel Nordigården, will deliver the keynote address on the “New Normal” at EskoWorld 2022 taking place June 7-9 at Gaylord Texan Resort in Grapevine, Texas. More than 500 packaging and label converters and brand representatives are expected to gather for the in-person event. The keynote will discuss which trends will be shaping the industry over the next five to 10 years, and how companies across the packaging value chain can address these trends to move toward their own “new normal.”

NADI announced that its new rosehip juice production factory near the Georgian capital of Tbilisi will run entirely on solar energy, which reduces carbon dioxide, saves tons of coal and eliminates the deforestation of hundreds of trees a year. Located in the village of Natakhtari, the factory relies on photo-voltaic cells to convert solar power directly into current energy to operate all equipment. Previously, the factory relied on imported electricity from the local municipality that consumes fossil fuels and drains other natural resources including trees and water. In the first few months since converting to solar power, the NADI factory reports saving 11,797 kg of carbon dioxide (13 U.S. tons); 4,744 kg of coal (5.2 U.S. tons); and protecting 650 trees from deforestation. The figures are expected to quadruple by the end of 2022, NADI estimates.