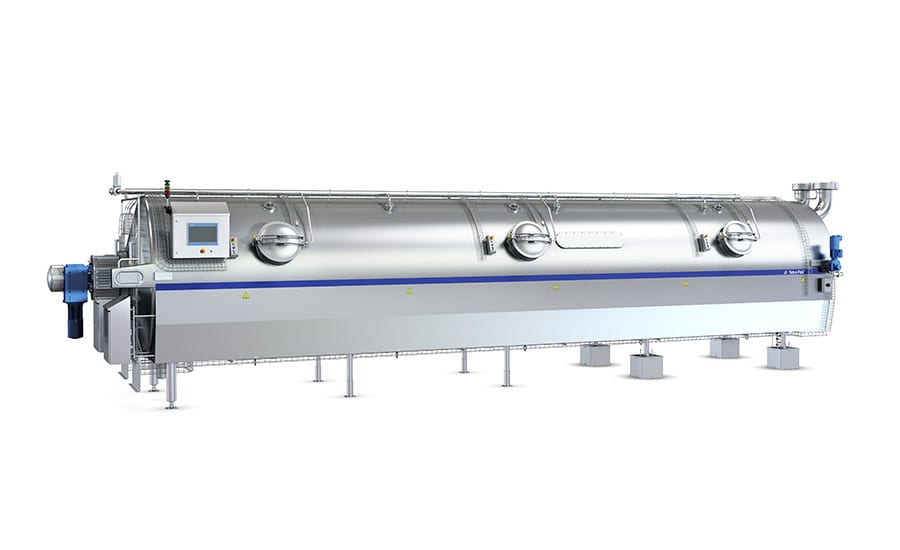

Tetra Pak’s Grainy Cheese Vat E4 is a fully automated horizontal curd-making vat designed for cottage cheese production. It features a totally enclosed system that meets USDA standards, ensuring a hygienic process by minimizing airborne contaminants. The vat includes a hot water-heated jacket for gentle curd cooking and agitator knives that produce consistent curd particle size. Next-level automation allows for uniform process control and ultimate repeatability. Available in capacities of 6,000, 12,000 and 18,000 liters, it is completely CIP-able (Clean-In-Place), making it easy to maintain. This innovative vat drastically reduces human interaction, enhances efficiency and ensures the highest product quality, making it a valuable addition to any dairy processing facility, the company states.

More InformationFULLY AUTOMATED VAT FOR COTTAGE CHEESE PRODUCTION