Innovative Solutions

Driven to Provide Value to Your System

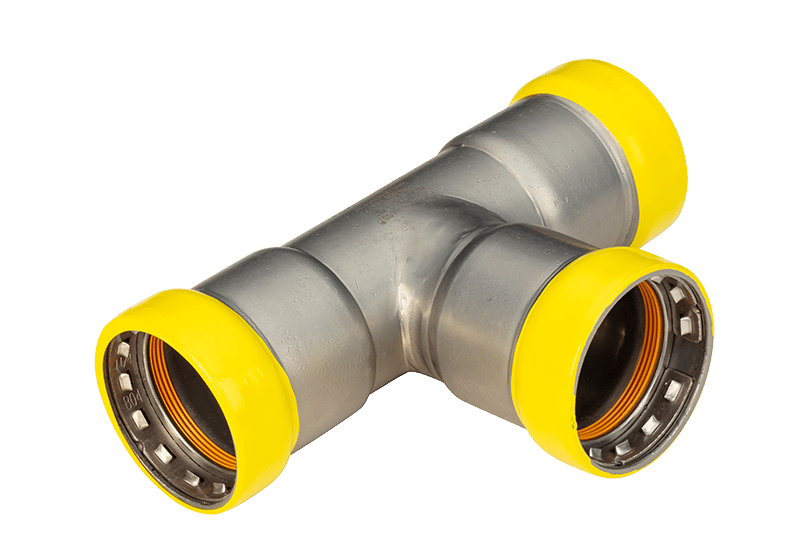

- Size Range: ½" – 2" (Fittings & Valves)

- Sealing Elements: EPDM (Water) & HNBR (Gas)

- Working Pressure: 300 psi

- Temperature Range: -4°F to 230°F (EPDM Fittings & Valves) -31°F to 248°F (HNBR Fittings) & -13°F to 248°F (HNBR Valves)

- 15-Year Limited Warranty on Fittings and 5-Year Limited Warranty on Valves

- IPS (Iron Pipe Size)

- Mates with S5 & S10, 304 & 316 Stainless Steel Pipe

- In Compliance with the Buy American Act

- Most Comprehensive Package with Over 325 SKUs

- Size Range: ½" – 4" (Fittings) and ½" – 2" (Valves)

- Sealing Elements: EPDM (Water)

- Working Pressure: 300 psi

- Temperature Range: 0°F to 250°F

(EPDM Fittings & Valves) - 50-Year Limited Warranty on Fittings and 5-Year Limited Warranty on Valves

- CTS (Copper Tube Size)

- Designed to be Used with ASTM B88 Type K, L, and M ½" – 2" Copper Tubing in the Hard-Drawn Condition and Soft Copper Tubing in Sizes ½" – 1-1/4"

- NSF 61 on Fittings

- Water Application Stamped on the Fitting as H2O in Green

- Fully Captured Grab Ring on 2-1/2" & Above

- Most Comprehensive Package with Over 350 SKUs

- Size Range: ½" – 2" (Fittings)

- Sealing Elements: EPDM (Water) & HNBR (Gas)

- Working Pressure: From Full Vacuum to 250 psi (17.2 bar) for Water and 125 psi (8.6 bar) for Gas

- Temperature Range: -40°F to 300°F (EPDM Fittings) & -40° F to 200°F (HNBR Fittings)

- 15-Year Limited Warranty on Fittings

- Iron Pipe Size (IPS)

- Suitable for Use on Steel Pipes Conforming to ASTM A53, A106, A135, A795 (schedule 10 to 40) and black iron, epoxy coated and galvanized steel

- Corrosion Resistant Zn-Ni Plating Ensures Years of Trouble-Free Service

- Grab Ring Deforms and Grips Outside Diameter of Pipe

- Application Stamped on the Fitting as H2O for Water and GAS for Gas

- Most Comprehensive Package with Over 400 SKUs

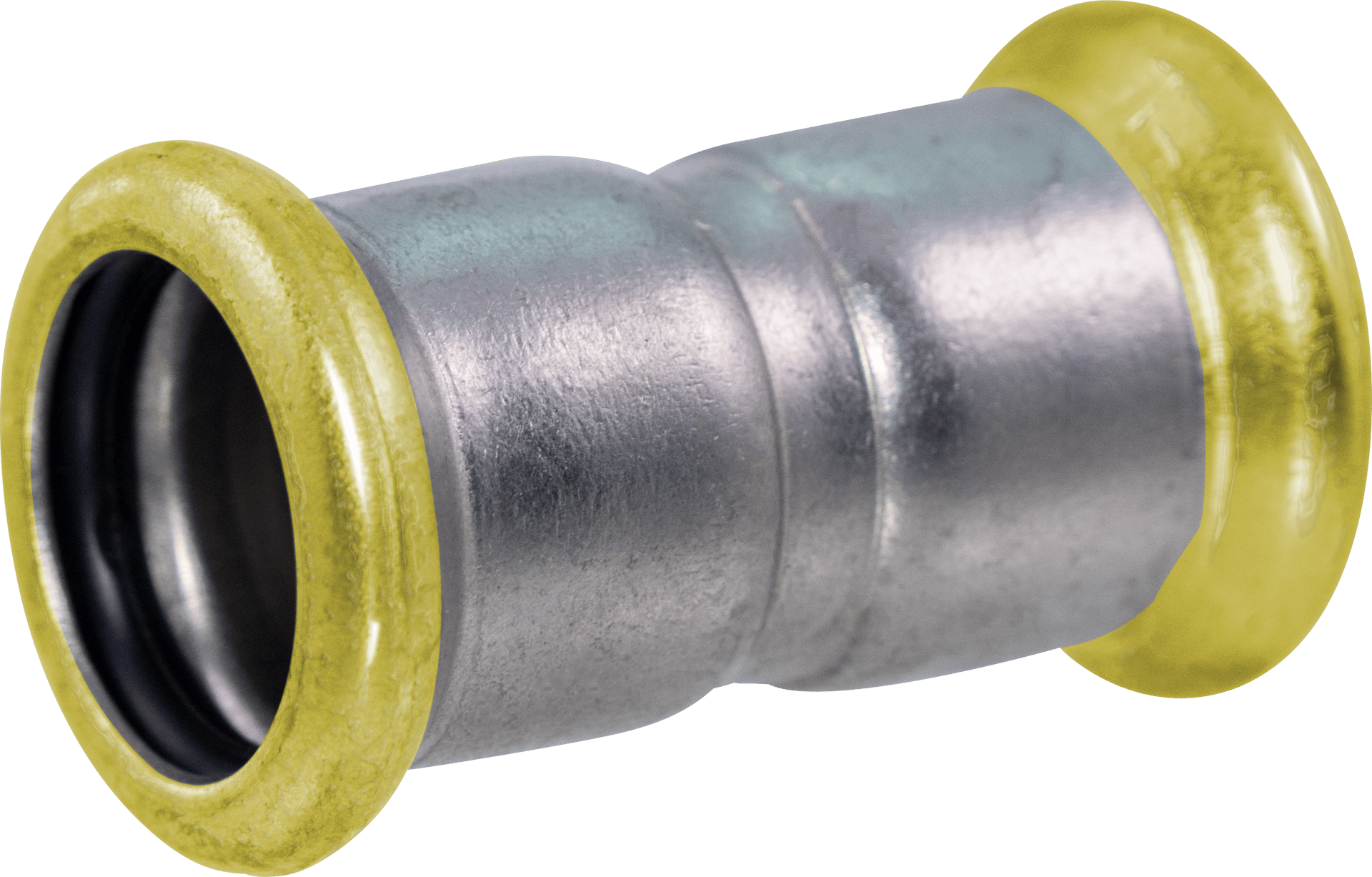

First to Market

The VIPR®, a patented technology that gives redundancy in identifying unpressed connections, is visible from 30 ft in the air to identify properly pressed connections. The VIPR® also indicates the sealing element material (green = EPDM and yellow = HNBR) preventing costly and potentially unsafe installation errors.

Visible Connections

Click on the circles for more

30-50%

Labor & Cost Savings Compared

to Other Joining Methods

From Planning to Projects to Training Through to Distribution

Innovative Solutions Driven to Provide Value

Streamlining Project Planning & Execution

BIM/Revit files for our press portfolio are available to download and use in the design of your systems.

Innovation with Design in Mind to Save Time, Money & Labor

Press systems are designed to provide the same quality and reliable pipe joint as other connection technologies while reducing the time to complete the joint; therefore, reducing the man-hours required for the entire project.

Training at Every Stage of the Process with Your Success in Mind

Each member of our sales & engineering team is qualified to provide job site product and installation training. This ensures that your experience with our press systems is a trouble-free experience.

Supporting Distribution Growth Strategies Through Vertical Market Relationship Building

Leveraging previous successful installations within a vertical market, or with an installer, helps to expedite growth.

Click on the plus signs for more

Documentation For Your Next Project

Dimensional

Catalogs

Submittal

Sheets

REVIT Files

Certifications

Dimensional

Catalogs

Submittal

Sheets

REVIT Files

REVIT Files

Certifications

Press Installations

How to Easily Install Press Fittings

Press Videos

22 Videos

View Playlist

CopperPress®

4 Videos

View Playlist

StainlessPress®

3 Videos

View Playlist

Press Systems

Cleveland, OH

Headquarters

Birmingham, AL

Distribution Center

Sparks, NV

Distribution Center

Long Beach, CA

Pipe Depot

Dallas, TX

Distribution Center

Houston, TX

Pipe Depot