EDITORIAL | BILL MAYER

News from the Aerospace Industry

There was a big announcement out of West Virginia in September that you may have missed. It was particularly big news for the aerospace industry.

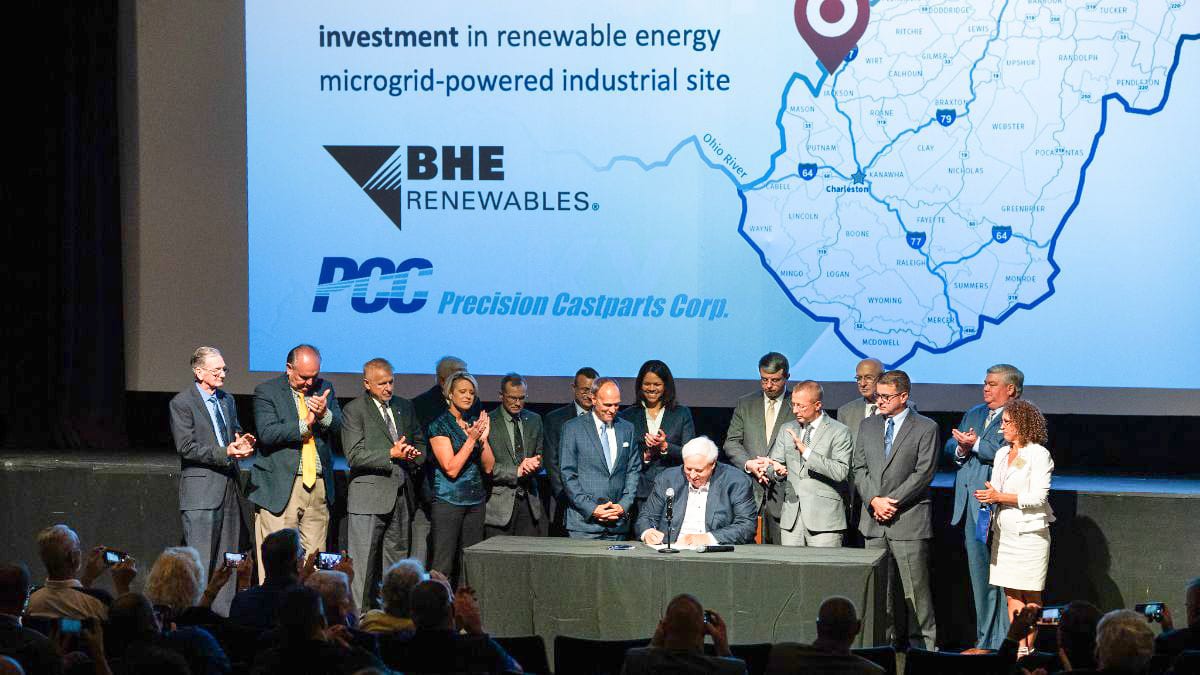

Governor Jim Justice announced that BHE Renewables, a Berkshire Hathaway Energy business, entered into an agreement with the State of West Virginia to purchase more than 2,000 acres of land in Ravenswood, W.V., to be developed as a global aerospace manufacturing hub. Precision Castparts Corp. (PCC), a Berkshire Hathaway Inc. business, will be the first company to locate on the site and will develop a titanium melting facility that will use 100% renewable energy to manufacture titanium products specifically for the aerospace industry.

“We are thrilled to partner with PCC and West Virginia to deliver this landmark renewable energy solution, hundreds of jobs and significant economic development,” PCC Metals President Steve Wright said of the $500 million investment. “Our future facility is an outstanding opportunity to use clean energy as we invest in further strengthening our position as a world leader in titanium metals.”

Image courtesy of the Office of the Governor Jim Justice

This announcement certainly isn’t the only news coming out of the aerospace sector in 2022.

In June, Collins Aerospace opened a new additive-manufacturing (AM) center in Monroe, N.C. The facility includes two 3D printers, with plans to add more. A month later in July, the Charlotte, N.C.-based company broke ground on a $14 million expansion of its AM center in West Des Moines, Iowa. The 9,000-square-foot expansion will allow Collins to make room for more 3D metal printers, in addition to the three it already has on site.

Boeing is investing $5 million to help expand the Advanced Manufacturing Innovation Center in St. Louis (AMICSTL). The new 130,000 square-foot advanced manufacturing facility will house workforce development programs, leading-edge R&D, and prototyping/production capacity spanning multiple “vertical” capabilities, including aerospace. The company also opened a new high-throughput small satellite production, integration and test facility in El Segundo, Calif., where Boeing and subsidiary Millennium Space Systems are applying advanced and additive manufacturing techniques, including 3D printing, to offer faster cycle times while improving performance.

Image courtesy of Collins Aerospace

Back in February, Airbus, Safran and Tikehau Ace Capital signed a Memorandum of Understanding with Eramet for the acquisition of its subsidiary Aubert & Duval, a supplier of critical parts and materials for the aerospace industry. The acquisition would allow Airbus and Safran to secure the strategic supply chain and new material development for current and future civil and military aircraft and engine programs.

Airbus also signed a partnership agreement with CFM International, a 50/50 joint company between GE and Safran Aircraft Engines, to collaborate on a hydrogen demonstration program. The program’s objective is to ground and flight test a direct combustion engine fueled by hydrogen. CFM will modify the combustor, fuel system and control system of a GE Passport turbofan to run on hydrogen. The engine is assembled in the United States.

In August, Aerobraze Engineered Technologies Oklahoma City was awarded a five-year contract with the United States Air Force (USAF). The contract includes the overhaul/remanufacture of F-15 fighter aircraft tubular heat exchangers and C-130 heat exchangers at the Tinker Air Force Base. Based in Oklahoma, Tinker Air Force Base is the headquarters of the Air Force Materiel Command’s (AFMC) Oklahoma City Air Logistics Center (OC-ALC), which manages aircraft, engines, missiles and more. In related news, the USAF awarded Aerobraze Engineered Technologies Oklahoma City a five-year contract for the remanufacture of F-15 fighter aircraft fin and plate heat exchangers at Mountain Home Air Force Base in Idaho.

Several furnaces and 3D printers have been ordered in 2022 that will be used for aerospace applications.

- SECO/WARWICK will supply a two-chamber vacuum melting and casting furnace to a company in the aerospace industry. The furnace is designed with vertical loading to produce high-quality equiax castings. According to SECO/WARWICK, this furnace is suited for the aerospace industry because it helps eliminate problems related to the finished quality of the cast parts.

- Ipsen installed a vacuum furnace at Temprasud, a commercial heat treater in Fresagrandinaria, Italy. According to Temprasud, the vacuum hardening and low-pressure carburizing furnace will increase its production capacity. The furnace, which has a 1,764-pound (800-kg) load capacity, will allow the heat treater to expand into the aerospace market.

- Sciaky Inc., a subsidiary of Phillips Service Industries (PSI), will deliver what it says is the world’s largest electron-beam directed energy deposition (DED) 3D printer to Turkish Aerospace Industries (TAI). The customized electron-beam additive-manufacturing (EBAM) system is going to TAI’s Ankara plant, where it will 3D print some of the largest titanium aerostructures in the industry.

- L&L Special Furnace Company Inc. shipped a large high-temperature box furnace to a Midwest plant starting production on ceramic matrix parts that will be used in aerospace applications. The furnace, which has been commissioned, is capable of reaching temperatures up to 3100°F (1700°C) under partial atmospheric pressure.

- Tech Castings LLC, a supplier of superalloy investment castings to the commercial and military gas turbine engine markets, initiated a $4.5 million expansion at its Shirley, Ind., manufacturing facility. As part of the expansion, the company ordered a vacuum precision investment-casting furnace from Consarc Corp. of Rancocas, N.J. When completed, the expansion will more than double Tech Castings’ current capacity of components for the aerospace industry.

- Lockheed Martin is using Velo3D’s metal 3D printer at its Additive Design & Manufacturing Center, which pilots new additive manufacturing technologies for production deployments in Lockheed Martin’s Space division.

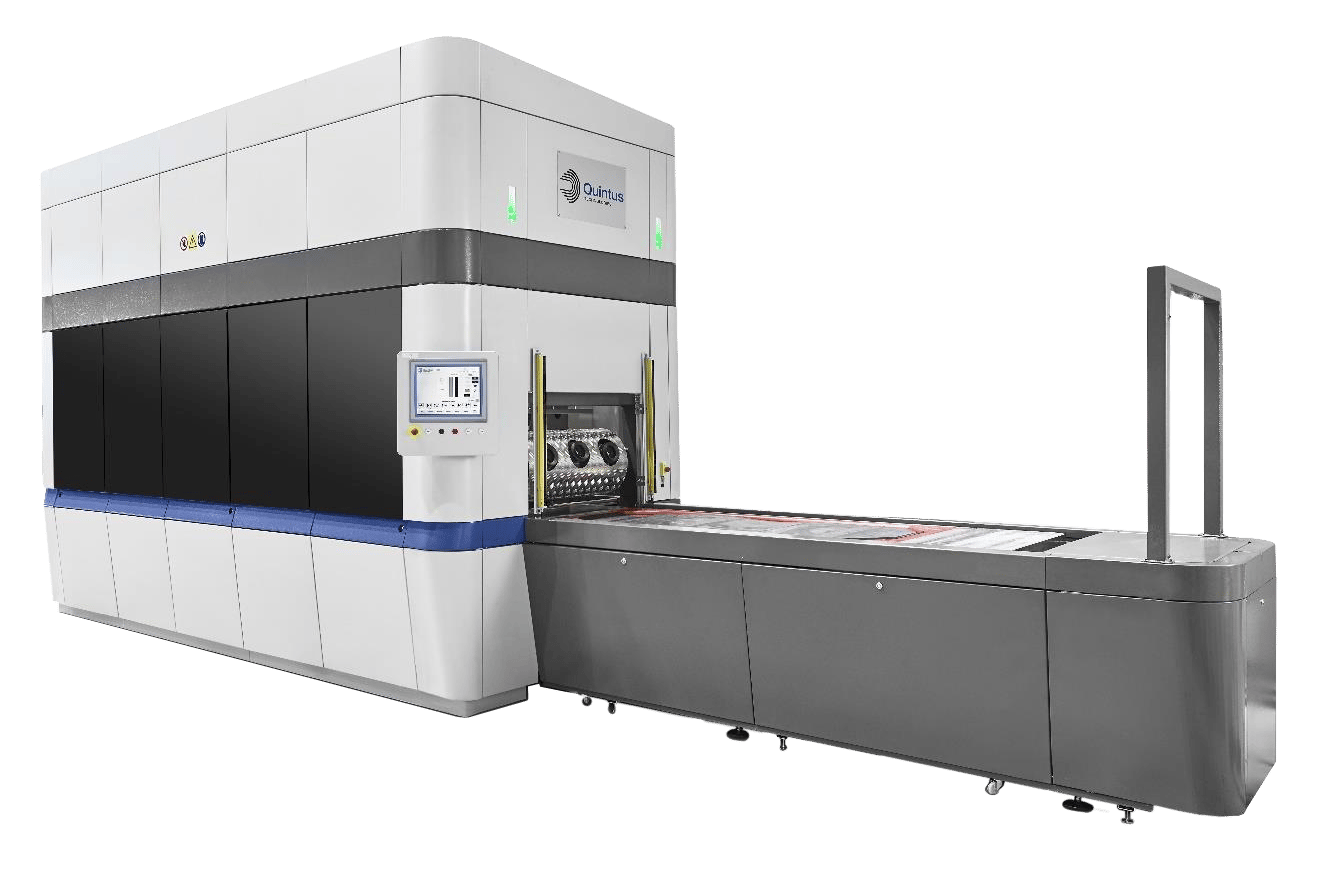

- A high-pressure fluid cell press from Quintus Technologies will boost efficiencies and lower production costs for Thailand’s Jinpao Precision Industry. The Flexform press will be used for forming aerospace parts for airplanes and helicopters.

Image courtesy of Quintus Technologies

This was just a brief sampling of some of the business- and equipment-related news from the aerospace industry thus far in 2022. Visit www.industrialheating.com and subscribe to our enewsletters to keep up-to-date with the latest industry happenings.