Cover story

Mass Timber: Sustainable and Enduring

The use of mass timber allowed HGA designers to innovatively embrace Bowdoin College’s commitment to carbon neutrality.

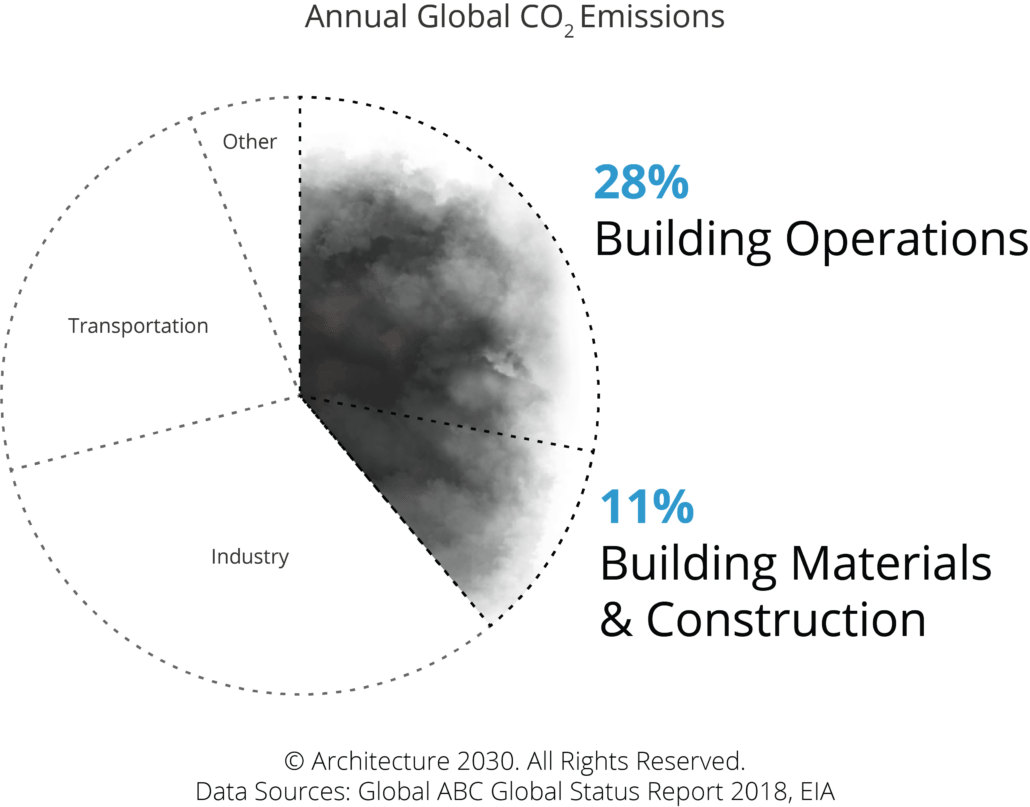

There has never been a more important time to take responsibility for our actions. The world is experiencing unprecedented rates of change in climate, energy supply, technology, and business. The climate crisis is urgent. The sixth Intergovernmental Panel on Climate Change (IPCC) Report, approved in April, states that carbon emissions must be reduced by 50% to ensure a livable planet in the future. Building construction and use contributes more than 40% of human-caused emissions of greenhouse gases. Designers of the built environment have a unique and inspiring opportunity to shape a positive future. This means developing the expertise and research to push beyond net-zero energy to net-positive energy, from a neutral effect on health, safety, and resources to a positive one.

Addressing Embodied Carbon

For years, the building industry has focused on reducing operational carbon — the total carbon from all energy sources used to keep buildings warm, cool, ventilated, lighted, and powered — through measures like energy efficiency improvements. While these reductions are important, they are additive solutions, meaning their immediate impacts are small relative to their projected impacts 60 years from now.

The other, more complicated piece of this equation is embodied carbon — the carbon arising from the manufacturing, transportation, installation, maintenance, and disposal of building materials. Because this type of carbon is spent before materials are even installed in a building, embodied carbon emissions have a much more immediate impact. According to Architecture 2030, embodied carbon will be responsible for almost half of total new construction emissions between now and 2050. This is a sobering statistic.

Understanding the collective responsibility to address embodied carbon immediately, the SE 2050 Commitment was developed to help ensure “substantive embodied carbon reductions in the design and construction of structural systems by the collective structural engineering professions.” Sponsored by the Structural Engineering Institute (SEI) and the American Society of Civil Engineers (ASCE), the SE 2050 Commitment challenges firms to transform the practice of structural engineering in a way that is holistic, firm-wide, project-based, and data-driven. As an early signatory to the SE 2050 Challenge, HGA hopes to lead by example: generating demand for materials and construction practices that serve this greater goal and creating a better future for all.

FIGURE 1: Annual global CO2 emissions by source. Building operations represents operational carbon and building materials represents embodied carbon.

Image courtesy of Architecture 2030.

Calculating Embodied Carbon

Embodied carbon is calculated with a life cycle assessment (LCA). It is directly related to material quantity, and reducing material reduces embodied carbon. To calculate the embodied carbon, it's necessary to have an understanding of material quantities at whatever stage of the project the LCA is to be performed. This can be done with estimated quantities, such as during the concept or schematic design phase, or with final design quantities, such as after a construction package issue, and anywhere in between.

For early phase analysis, structural engineers can use material tonnage averages or representative bay studies to estimate the embodied carbon for the entire structural system. This is especially useful to compare two or more systems early in design, say steel and mass timber. A great tool for this level of analysis is the SE 2050 ECOM. An engineer can simply input material quantities from a takeoff to see embodied carbon intensity. This tool uses industrywide environmental product declarations (EPDs), which operate like nutrition facts labels, to quantify the environmental impact and embodied carbon of various building products and materials.

For analysis in later phases of a project, software programs like Tally and OneClick LCA are robust options. Tally requires a Revit model, and OneClick can reach its full potential with a Revit model. These programs can pull exact material quantity from the Revit model and allow an engineer to assign an appropriate EPD to determine embodied carbon. OneClick allows a user to add in other materials, such as those not modeled in Revit, and adjust material quantity, transportation distance, and method.

FIGURE 2: In addition to its embodied carbon benefits, mass timber provides the rhythm for a simple and elegant facade.

Image courtesy of Consigli Construction Co. Inc./Robert Umenhofer Photography

Reducing Embodied Carbon

Architecture 2030 reports that just three materials used frequently in structural and architectural systems — concrete, steel, and aluminum — account for 23% of annual global carbon emissions. Less intensive carbon alternatives, like mass timber, provide a viable structural solution while carrying embodied carbon advantages. For an efficiently designed structure, mass timber is naturally a lower embodied carbon choice than either concrete or steel because there are less emissions embodied in its production. The largest contributor to concrete is the production of Portland cement, an energy-intensive process whose chemical reaction itself has associated emissions. Production of steel, while it can be repeatedly recycled, is still an energy-intensive process with emissions. Mass timber can also help to reduce a building’s embodied carbon footprint by accounting for the carbon naturally sequestered during a tree’s growth cycle. Once a tree is harvested, this carbon is locked within the timber for as long as it remains intact and helps to offset the carbon required to harvest, transport, fabricate, and erect the structure. This natural carbon sequestration, or biogenic carbon storage, is unique to timber. Thus, by using sustainably harvested timber instead of steel or concrete, project teams can significantly reduce the amount of carbon required to construct a building, helping to move the construction industry toward means and methods that are less damaging to the environment.

There are several unknowns and assumptions to be aware of when it comes to calculating the actual amount of stored carbon in wood. Forest management practices can have a significant impact on the embodied carbon but are likely unknown to the specifying engineer. Specifying Forest Stewardship Council (FSC)- or Sustainable Forestry Initiative (SFI)-certified wood is a way to help ensure sustainably grown and harvested wood, though it doesn’t guarantee a specific quantity of biogenic carbon. Manufacturer EPDs, if available, can help to account for the impact of forestry management practices. End-of-life scenarios for wood products are also critically important but may be hard to know for a specifying engineer. The carbon may be sequestered in the wood for the life of a building, but if that wood is landfilled or incinerated at the end of its life, that carbon is released into the atmosphere which means the benefit of biogenic carbon storage cannot be accounted for in the life cycle of the product. This does not mean specifying wood without knowing its end-of-life scenario is a bad idea. With wood’s lower carbon footprint, not including biogenic carbon, it is still a less-intensive material, and markets for recycled and reused wood may be significantly changed in 60 years. Specifying more mass timber now may even help the industry get there quicker.

FIGURE 3: The wood structure pulls nature into the interior of the Center for Arctic Studies at Bowdoin College, bringing its occupants closer to their environment.

Image courtesy of Consigli Construction Co. Inc./Robert Umenhofer Photography

A Catalyst for Research and Dialogue: Bowdoin College

Located in midcoastal Maine, Bowdoin College is a liberal arts school with a strong commitment to environmental issues and social justice. The school prides itself on its dedication to environmental stewardship. In June 2007, Bowdoin joined 270 colleges and universities in signing the American College and University Presidents Climate Commitment and pledged to achieve carbon neutrality by 2020. In April 2018, carbon neutrality was attained two years ahead of schedule, making Bowdoin only the third college in the country to have achieved its commitment.

The college’s new John and Lile Gibbons Center for Arctic Studies, designed by HGA, currently under construction by the builder, Consigli Construction Co. Inc., uses mass timber as the core structural system not only to reduce its embodied carbon footprint but also for the beautiful and long-lasting interior aesthetic timber provides. The project will be among the first complete mass-timber structures in Maine and commercial structures in the state to utilize a mass-timber shear wall system to resist wind and seismic loads.

Bowdoin was one of 10 institutions to receive funding from the U.S. Forest Service, in partnership with the U.S. Endowment for Forestry and Communities Inc., a nonprofit corporation that works collaboratively with partners in the public and private sectors to advance systemic, transformative, and sustainable change for the health and vitality of the nation’s working forests and forest-reliant communities. The grant assisted Bowdoin in developing this innovative and sustainable approach to the building’s structural system.

“Sustainable structures are the way of the future,” said Matt Tonello, director of operations for Consigli’s Maine office, the general contractor for the project. “I think the reduced carbon impact that results from utilizing renewable methods speaks to the way we should be constructing buildings moving forward.”

FIGURE 4: The mass-timber framework of Bowdoin’s Center for Arctic Studies supports the college’s ongoing commitment to sustainability.

Image courtesy of Consigli Construction Co. Inc./Robert Umenhofer Photography

During design, HGA and Consigli worked to thoroughly vet the possibility of a mass-timber system. The team analyzed a mass-timber design as well as a traditional steel design for comparison. Mass timber, in this case, is comprised of glued-laminated timber (glulam) beams and columns with cross-laminated timber (CLT) floor decks, roof decks, and shear walls. To confirm schedule and cost equivalence, Consigli completed a 4D structure erection schedule analysis and cost analysis of the timber structure against the steel option. The model found that the timber option could achieve a fully erected and enclosed structure months ahead of what would have been possible with standard steel construction methods. To quantify possible carbon savings, HGA performed an LCA on both the mass-timber and steel options, finding that mass timber cut the embodied carbon of the structure to roughly 25% of the comparable steel structure.

“The ability to use mass timber really enabled us, as the design team, to embrace the college’s commitment to carbon neutrality in a new way,” said Lauren Piepho, structural engineer for HGA. “The result is a structure that is not only beautiful but functional and sustainable.”

Challenges of Mass Timber

Mass timber suppliers are still not as prevalent in the U.S. as they are in Europe. It can often be more cost-effective to ship timber from Europe rather than sourcing it in the states. However, new CLT plants are being introduced in the U.S., including a new one in Arkansas that has just opened.

At present, Woodworks — an organization that represents wood suppliers — indicates that 603 mass timber projects have been built in the U.S. with 700 more currently in the design phase. Although most mass timber projects are focused on the coasts, every state now has a mass timber project either constructed or in design. And, while mass timber is still new to most contractors, it has construction advantages. For Bowdoin, working with a fully mass-timber building presented some unique challenges that required an early collaborative effort between the Consigli preconstruction team and subcontractors to achieve a fully coordinated mechanical, electrical, and plumbing (MEP) infrastructure to incorporate into the timber structure. This coordination team was tasked with modeling every piece of conduit that would interact with the timber in a 3D, virtual world to ensure the final installation was laid out and organized. Every penetration within the timber required structural review prior to fabrication, which was started nearly a year ahead of the work. With increased demand for spaces that are sustainable, flexible, and efficient, the U.S. has quickly caught on to the advantages mass timber affords.

As the technology behind mass timber continues to develop and markets realize the full economic and environmental benefits, the use of mass-timber building systems is projected to blossom. As Michael Green, mass-timber construction and design specialist noted at a TED Talk in 2013, “I’ve never seen anybody walk into one of my buildings and hug a steel or a concrete column, but I’ve actually seen that happen in a wood building.”

Ethan Fogle, P.E.

Ethan Fogle is a structural engineer at HGA with a wide range of experience in many project types, including government, corporate, health care, and arts facilities. He combines broad technical project experience with expertise in embodied carbon and life cycle assessment (LCA). He’s passionate about understanding human kind's deep connection to the natural world while actively and creatively reducing the impact of the planet's buildings. Fogle's curiosity and collaborative approach deliver thoughtful, inspired, and cost-effective solutions for our clients and project teams. A strong advocate for sustainable design, he is a member of the American Society of Civil Engineers (ASCE)-SEI Sustainability Committee, a member of HGA's Sustainability Steering Committee, and HGA's SE 2050 Embodied Carbon Champion.

HGA's Lauren Piepho and Tony Staeger also contributed to this article.

Image courtesy of Consigli Construction Co. Inc./Robert Umenhofer Photography