Top 10 New Plant Products of 2023 - Part 2

FOOD ENGINEERING’s

Top 10 New Plant Products of 2023

These are the manufacturing plant products that you, the readers, were most interested in throughout the past year.

Video courtesy of Getty Images / cinquefx

#5

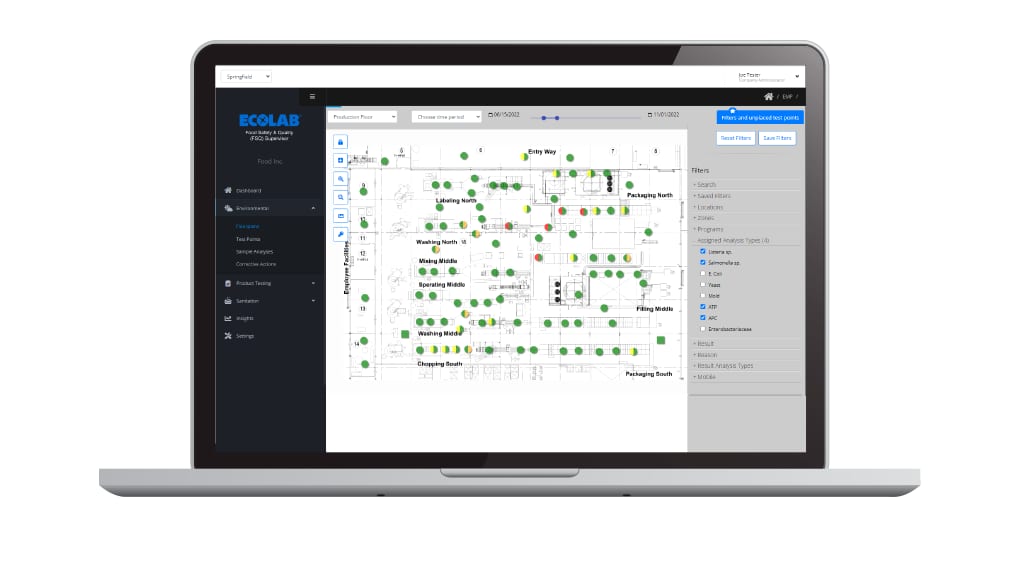

Digital Platform to Simplify Food Safety & Quality Management

Ecolab has launched Food Safety and Quality (FSQ) Supervisor, a web-based platform designed exclusively for food and beverage manufacturing to gather and report food safety & quality (FS&Q) data.

Ecolab FSQ Supervisor Platform is designed to simplify food safety and quality for food and beverage manufacturers by turning manual FS&Q data collection into proactive issue mitigation and actionable insights. The outcome-driven platform reportedly enables F&B manufacturers to use their FS&Q data to increase sellable product, reduce testing costs, mitigate recall risks and streamline regulatory compliance.

FSQ Supervisor provides food and beverage producers with actionable decision-making insights across the entire food and beverage process in one web-based system:

• Environmental Monitoring: Records sampling and testing

• Test Point Management: Provides automated alerts for adhering to testing standards

• Interactive Dashboards: Shares relevant analytics with authorized users

• SOP Management: Provides instructions for critical control points

• Cleaning Verification: Ensures observance of methods, procedures and tests

• Reporting: Allows automation of internal and audit and quality reporting

• Floorplan Visibility: Offers an interactive, birds-eye-view of sample points

• Strong Security: Ensures that only authorized users have access to data and insights they need to perform their jobs

The modular platform allows users to selectively deploy a phased approach to simplify digital transformation and align with existing workflows.

Image courtesy of Ecolab

#4

Fluke ii910 Precision Acoustic Imager

Fluke Corp. has introduced the ii910 Precision Acoustic Imager with the new MecQ Mode, which allows maintenance technicians to scan large areas and pinpoint technical issues before they become critical. With the Fluke ii910, technicians can now see what they can’t hear in an effort to identify problems across large conveyor systems.

With its user-friendly interface and point-and-scan visualization, the goal of the Fluke ii910 Precision Acoustic Imager with MecQ Mode is to provide a solution that simplifies maintenance workflows. It is designed for mechanical maintenance professionals to focus on specific areas of interest, ensuring detection and targeted maintenance. It reportedly filters out industrial noise, even in challenging conditions. With contactless scanning, the system allows technicians to access hard-to-reach areas from a distance, reducing risks on the job.

The ii910 is part of the Fluke suite of acoustic imagers that allow maintenance technicians to visually pinpoint leaks in compressed air, gas, steam and vacuum systems, and partial discharge in high-voltage power lines, insulators and transformers. With the addition of the MecQ Mode on the ii910, teams can visualize potential issues with conveyor systems before they lead to downtime.

MecQ Mode is available now on all Fluke ii910 Precision Acoustic Imagers. For existing customers, MecQ Mode will be added through a free firmware upgrade.

Image courtesy of Fluke

#3

HazLoc-Compliant Metal Detectors

METTLER TOLEDO Product Inspection Group has introduced metal detectors for hazardous locations. Designed for manufacturing environments where dust-producing products can create an explosive atmosphere, these cETLus-certified systems adhere to construction standards, fulfilling the requirements for Class II, Division 2 Hazardous locations. By minimizing the risk of explosions in these environments, HazLoc-compliant metal detectors help processors and packers improve worker safety, safeguard their facility and protect their brand’s reputation while meeting regional compliance requirements.

HazLoc construction is available for Mettler-Toledo’s gravity-fed metal detectors, including the Profile Gravity Flow (GF) series, Profile Throat (T) series and Profile Super Throat (ST) series, which are suitable for free-falling powders, grains and granules including flour, sugar, coffee grains and other foods as well as pharmaceutical, nutraceutical, cosmetic, personal care and chemical applications.

HazLoc-compliant metal detectors feature dust-tight enclosures, intrinsically safe components and qualified accessories. Dust-proof electrical wiring and sealing meets NEC standards. Red color-coded gaskets provide easy identification of HazLoc-compliant components. Construction materials dissipate static electricity to specified grounding locations to ensure static charges are safely removed from the system.

Image courtesy of METTLER TOLEDO

#2

Siemens’ SINAMICS S200 Servo Package

Siemens’ SINAMICS S200 servo, which features a SINAMICS S200 drive and SIMOTICS S-1FL2 motor, comes with standard or flexible cable options. Siemens states that the new servo brings a new level of motion control to the standalone and networked machine market.

SINAMICS S200 servo package expands the SINAMICS drive offering various applications to the servo market. The pulse train version allows a range of installed machines to integrate additional positioning axis using the onboard positioner. Meanwhile, a dynamic networking capability for motion control, i.e., SIMATIC PLC, expands its system capabilities in the PROFINET version. With a power range of up to 7 kW including low-, medium- and high-inertia features, the S-1FL2 permanent magnet motors with 17- or 21-bit encoders expand the performance and scale to the widest range of standard servo requirements.

The company states that easy setup is assured with the electronic type plate on the S-1FL2 motor and one-button tuning in the S200 drive. The integrated brake resistor and integrated holding brake control add to the functions of the S200 servo-drive. Reportedly, high durability is designed with the coated circuit boards (3C2) in the S200 and IP65 with a metal connection solution. Built-in under-voltage protection is further provided.

Image courtesy of Siemens

#1

Ecolab No-Rinse Sanitizer

Ecolab’s Active OX+ (EPA Reg. No. 1677-275) is a no-rinse food contact sanitizer, listed by the U.S. Organic Materials Review Institute (OMRI).

The new, EPA-registered sanitizer is designed for use on hard, non-porous and pre-cleaned food contact surfaces such as pipelines, tanks, vats, fillers, evaporators, pasteurizers and associated equipment in facilities including dairy processors, beverage and food processing plants, and breweries.

With Active OX+, Ecolab says organic food and beverage producers will:

• Enhance quality assurance with consistent sanitization efficacy across a broad effective range of use concentration—including no-rinse efficacy against biofilms. Conductive chemistry will also allow real-time tech-driven monitoring and controls to further support quality assurance.

• Simplify operations and drive efficiencies by reducing chemistry, water, and energy usage with a concentrated formula that achieves effective sanitization with up to 50% less chemistry—as compared to Oxonia Active (EPA Reg. No. 1677-129).

• Aid productivity and performance by streamlining clean-in-place sanitization and significantly reducing the need for acid washing.

• Support safe, sustainable operations with quick-connect drum probe technology that minimizes employee exposure risks during drum and tote changeovers. Active OX+ will also reduce chemistry and resource usage and improve effluent quality to mitigate negative environmental impacts. FE