LEADING EDGE

Eco-Products // ecoproducts.com

Eco-Products Introduces New Compostable Sandwich Wrap

With more restaurants seeking carryout and delivery options, Eco-Products is introducing a new compostable wrap designed for swaddling sandwiches, snacks and more. The new wrap is made from wax paper, is ASTM D6868 compliant and is certified by the Biodegradable Products Institute (BPI) as compostable in commercial facilities. It works as a basket liner, food wrap or as a scale or pick-up sheet. Jointly developed with Eco-Products’ parent company, Novolex, the new wrap offers a number of benefits: it works with both hot and cold snacks and sandwiches, it’s made from renewable resources, it’s grease- and moisture-resistant, and more.

Photo courtesy of Novolex

INX International Ink Co. // inxinternational.com

New Ink Products for the Shrink Sleeve Market

INXFlex Contour is a dynamic UV and LED dual-cure flexographic ink system designed to help produce distinctive shrink sleeve label solutions for brand owners. INXFlex Contour follows the introduction of Genesis GS washable label inks, a recycle-friendly product that recently added a new flexo version and UV Curable primer that makes INXFlex Contour washable too. In addition to high-performance capabilities, these colorful and vibrant inks were designed to address pertinent brand owner issues including efficiency and sustainability.

Photo courtesy of INX International Ink Co.

Multi-Conveyor LLC // multi-conveyor.com

Multi-Conveyor Flush Grid Replaces Wire Mesh

Multi-Conveyor recently announced its high-level hygienic 48-in.-wide flush grid and side flexing plastic conveyor belt solution to replace an existing wire belt system and for more sanitary constructed conveyor. Product discharges in multiple lanes from the customer oven to the Multi-Conveyor infeed. Rows uniformly convey through a slight incline then end transfer to a side-flexing 35-degree curve which maintains orientation required for accurate spacing and placement for the freezer infeed ahead. The upgraded belting provides a much smoother transition in product transfer areas.

Photo courtesy of Multi-Conveyor LLC

Shemesh Automation // shemeshautomation.com

Jumbo Wipes Bagger from Shemesh Automation

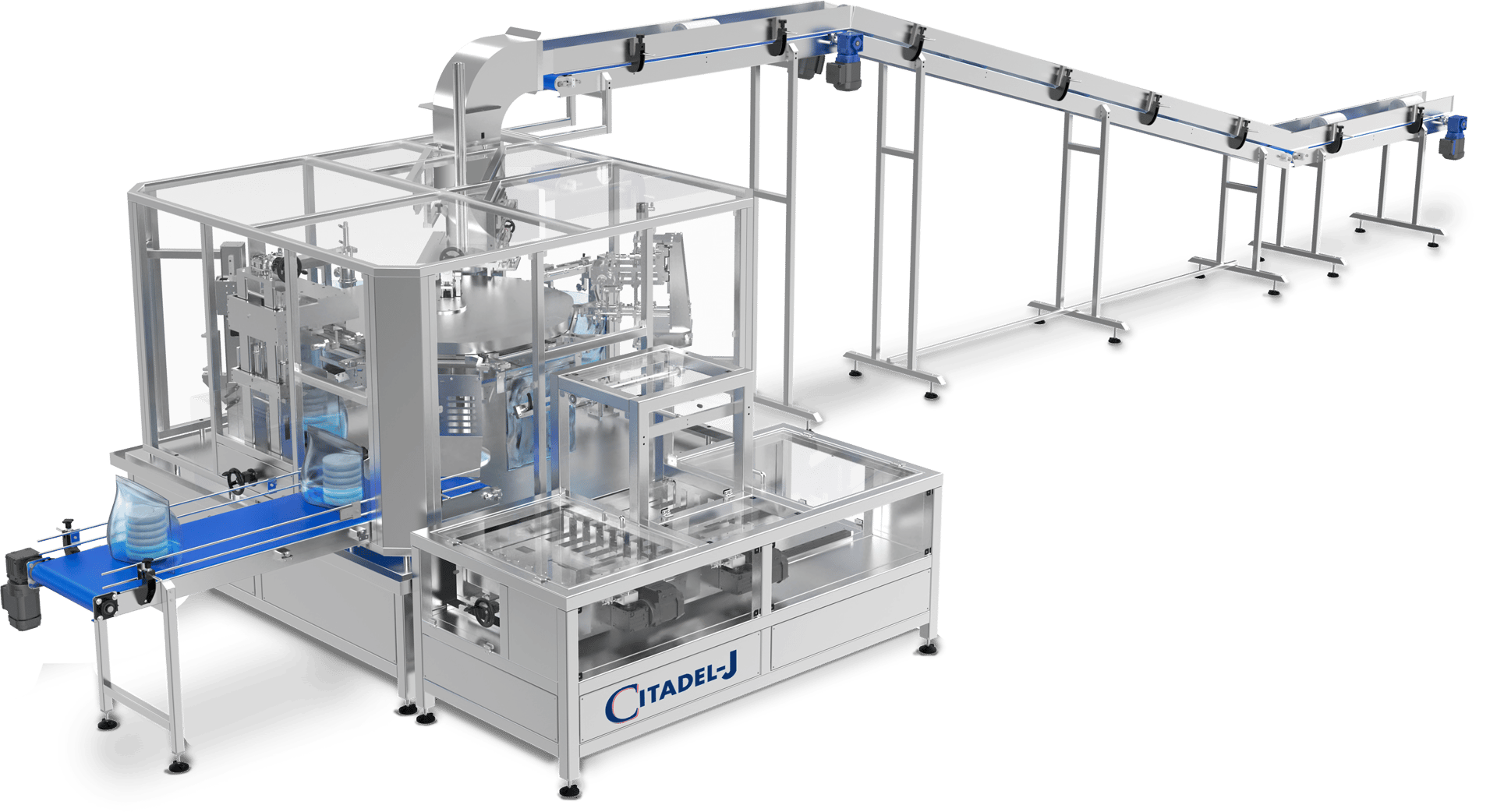

Shemesh has developed the CITADEL-J, a solution for manufacturers of wipes in flexible jumbo-sized bags who are looking to enhance their production with fast, space-saving automation. A standalone monobloc unit, the CITADEL-J automatically stuffs jumbo sized (typically in the 600 sheet-count to 1,200 count range) nonwoven rolls into premade bags, accurately fills them with liquid (typically 3 to 5 liters) while providing constant support beneath the heavy bag, seals the bags and then ejects the finished product at speeds of 10-15 packs per minute (depending on product-specific variables).

Photo courtesy of Shemesh Automation

Grounded Packaging // groundedpackaging.co

New Post-Consumer Recycled Film Laminate Made from Recycled Materials

Grounded Packaging announced the launch of RE: MONO, a new recyclable, flexible packaging solution made of 83% recycled materials. The new product contains the highest volume of post-consumer recycled content currently available in the world for food contact pouches and other flexible packaging formats, according to the company. The new film laminate offers food manufacturers a sustainable alternative packaging solution to traditional products that are often non-recyclable and end up in landfills and the environment. The film laminate is made from disposed plastic from recycling streams, such as milk bottles and plastic bags.

Photo courtesy of Grounded Packaging

August 2022 // flexpackmag.com