CORPORATE PROFILES

Sezeryadigar/iStock/Getty Images Plus via Getty Images

Ajax/CECO/Erie Press (A.C.E.)

Ajax/CECO/Erie Press (A.C.E.) knows forging equipment and parts. The merger of two century-old, highly regarded press manufacturers has transformed into North America’s largest and most versatile equipment supplier. A.C.E. would like to take this opportunity to thank their customers and employees for their loyalty for over 270 collective years of operation. What better way to give back to the #forging industry than to deliver custom solutions of high value, quality #Parts, #Equipment and #Service to their customers, optimizing the forging and forming industry segments.

Programs are offered within the customer’s budget and allows them to keep forging successfully: stocking and PM programs, OEM training and service. With the shortage of experienced and willing laborers, these programs, along with optional control upgrades, can enhance the new generation’s capabilities and increase understanding of how critical forging is to America’s strength and stability in the world. Let Ajax/CECO/Erie Press support you!

#KeepForgingAmerica

Image courtesy of Ajax/CECO/Erie Press

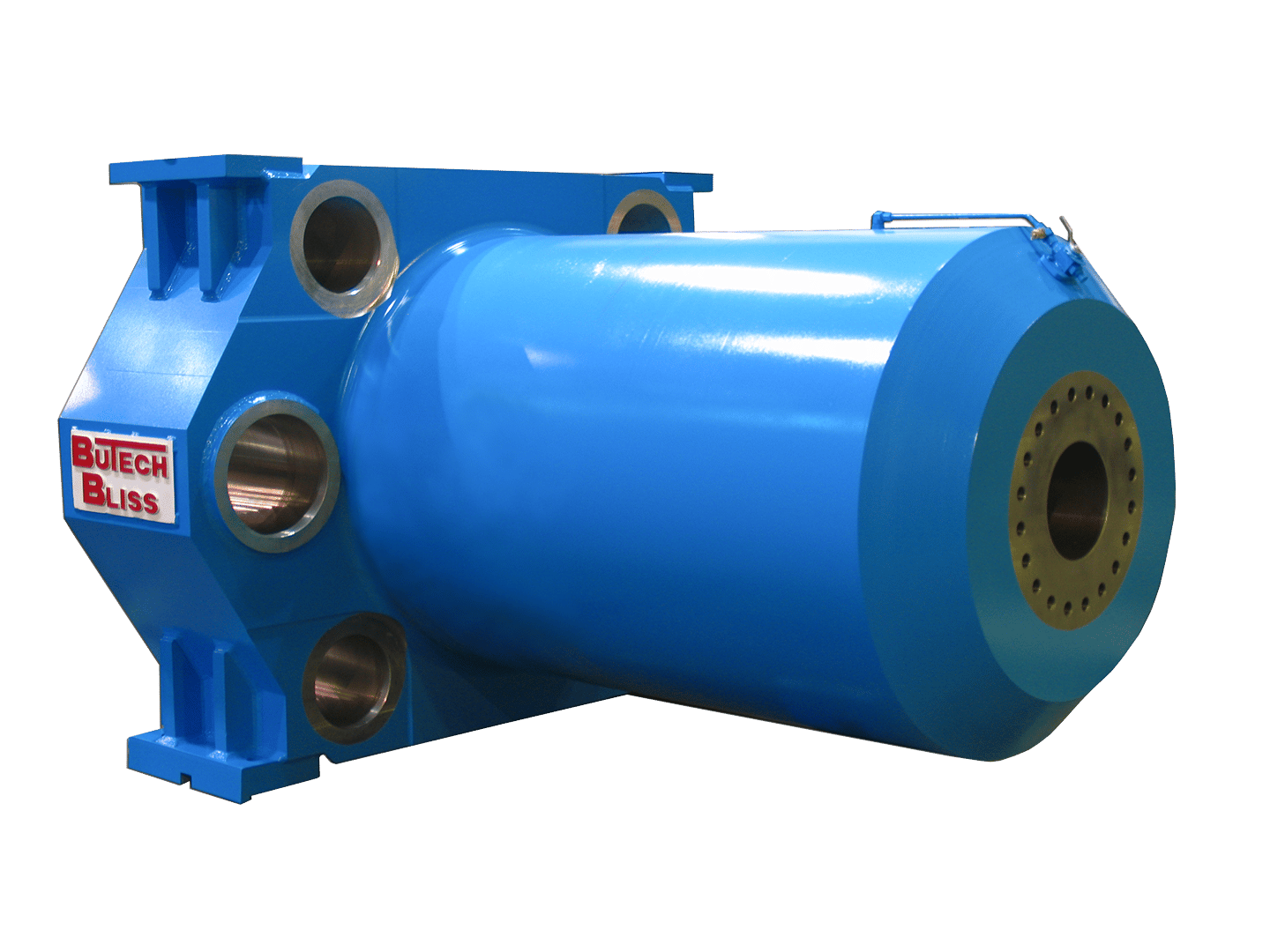

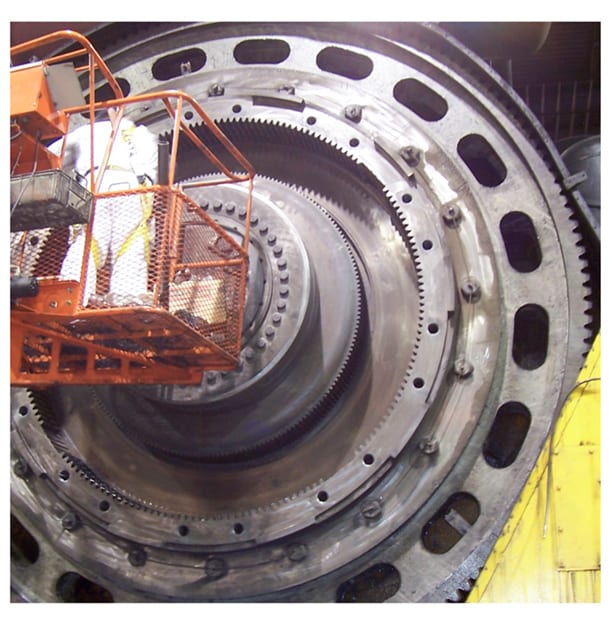

Butech Bliss

Butech Bliss is a leading innovator providing equipment solutions for extruders and forging companies for over 135 years. Some of our most valuable services include main cylinders, main rams, platens, crossheads, containers, container housings, butt shears, tie rods, billet loaders, die shuttle systems, engineering studies and FEA analysis.

We provide custom-built equipment to fit your circumstances, not standard designs that may not be the best solution for your particular application. The Butech Bliss advantage means equipment designed to maximize your return on investment through longer life, less maintenance and higher productivity.

www.ButechBliss.com

Image courtesy of Butech Bliss

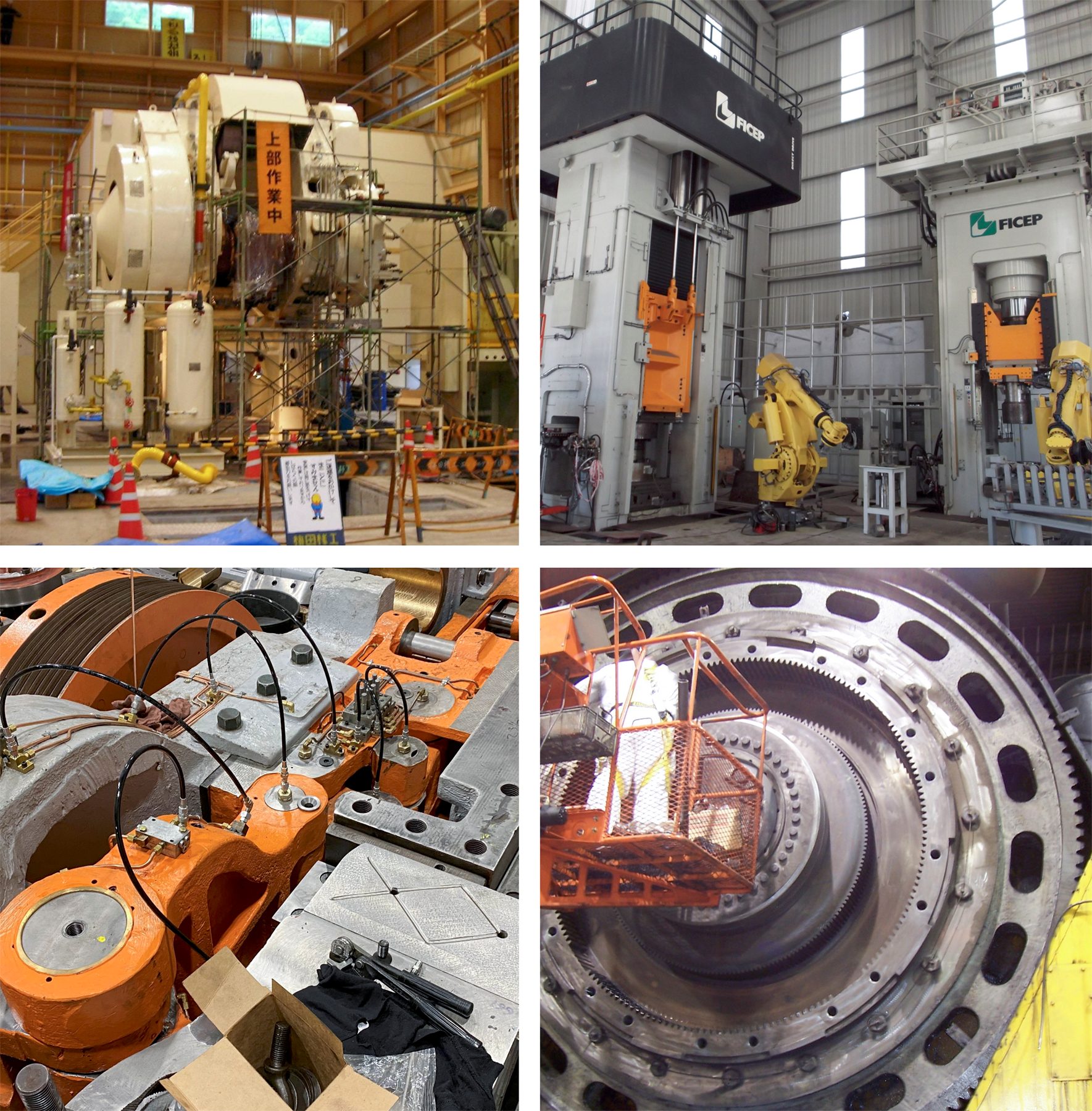

Campbell Press Repair

Since 1973, Campbell has provided quality repair and rebuilding services for forging equipment. We work on hammers; upsetters; and mechanical, screw, trim and hydraulic presses. Our service encompasses emergency work, on-site welding and machining, field services for inspection, disassembly, repair and assembly work. In our Lansing Mich., plant, our skilled technicians can repair worn, cracked or broken parts through welding and machining or by reverse engineering and making new replacement parts. Our rebuilding typically includes updates such as new controls, lubrication and automation. We also represent FICEP Group for new forging presses, saws and shears.

www.campbellpress.com

Image courtesy of Campbell Press Repair

Heat Treat Furnaces (HTF)

For over 30 years, Heat Treat Furnaces (HTF) has been designing, fabricating and installing custom industrial heat-treat furnaces for our clients. HTF’s experienced engineers and support staff are focused on your project. Our industrial furnaces have an extensive list of capabilities and can be manufactured to suit almost any application. We are a full-service supplier, meaning we assume responsibility for all mechanical, electrical, structural and control aspects of our furnaces. When you purchase an HTF furnace, you get complete engineering support, evaluation, testing, design, fabrication, installation, start-up and field service with the continued support from our in-house service team.

www.heattreatfurnaces.com

Image courtesy of Heat Treat Furnaces (HTF)

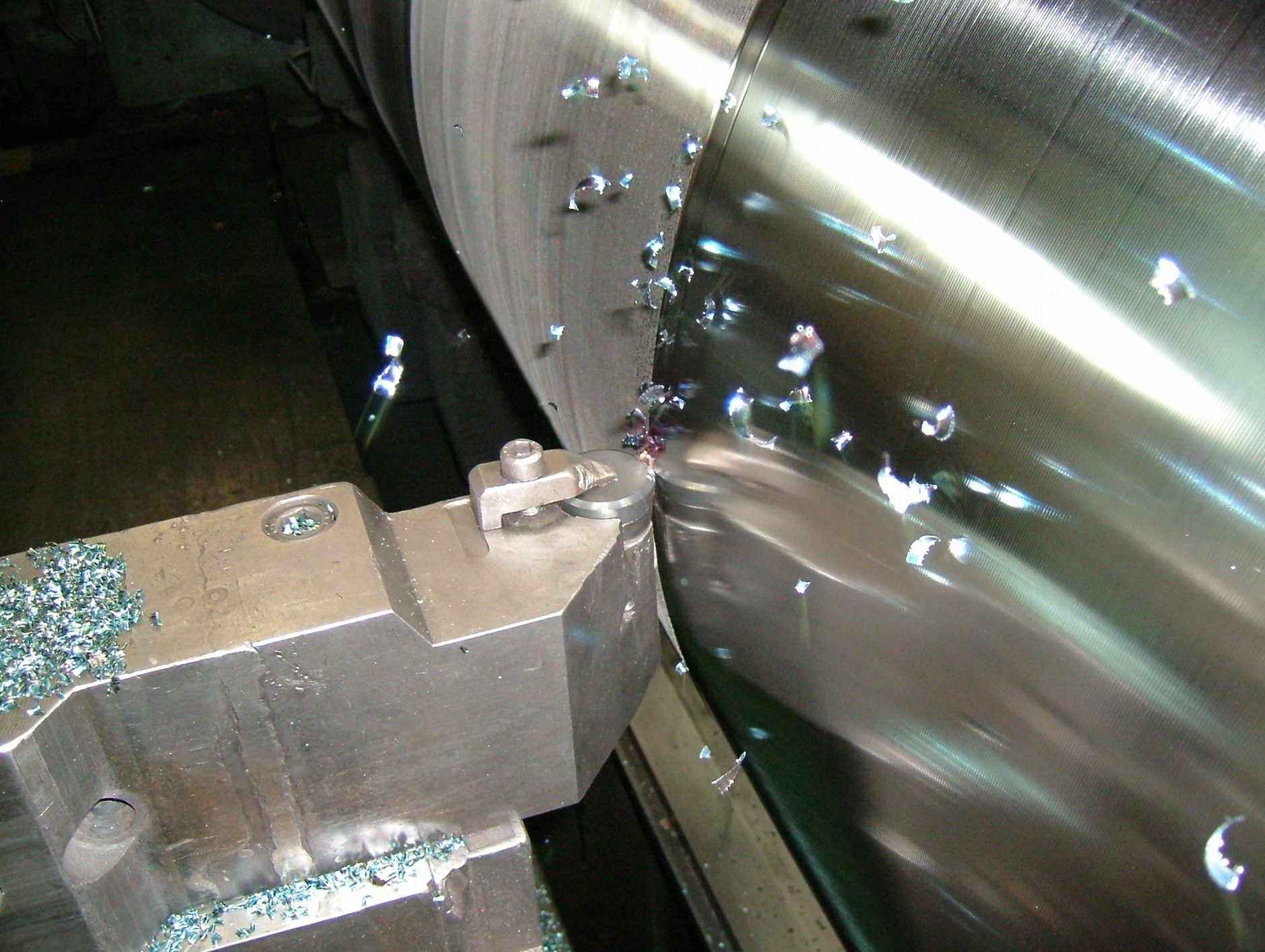

NTK Cutting Tools

NTK customers benefit from extended tool life, improved part surface finish and cost-saving solutions when running our Alumina-TiC black ceramic inserts. The highest quality selection of ceramic and CBN tools ensure high productivity in demanding steel mill and forge applications. HC2’s success led to newer grades to machine an array of workpiece materials. HC5, HC7 and ZC7 ceramics with unique grain structure are designed to machine hardened steels (50-62Rc) and effectively machine chilled or ductile iron rolls. ZC7 handles soft to hard turning applications. HC5 also performs well cutting powdered metal materials. ZC4 grade, with its fine grain structure, machines steel up to 70Rc and is ideal for finishing.

Implementation of RCGX103P8015 HC7 profiling a cast iron roll along a 27.6-inch LOC (at 650-800 SFM, feeding at .010-.015 IPR) through varied DOC resulted in more effective high-speed machining while also reducing tool costs for the customer with extended life per cutting edge.

Applications where CBN is the preferred tool, NTK’s multi-edge inserts are cost-effective solutions. To help customers tackle carbide roll machining, we apply our B30 or B99 inserts. Machining hardened materials where the insert encounters interruptions, NTK provides tooling solutions for various cutting conditions from B52, B5K, B36, B6K and B40 grades.

www.ntkcuttingtools.com/us

Image courtesy of NTK Cutting Tools

Postle

Hardface Technologies by Postle offers a complete range of hardface welding alloys to protect equipment and components from wear caused by abrasion, impact, metal-to-metal friction, erosion and cavitation. Postle can customize products to fit your needs and provide technical expertise on the application of welding products.

Manganese and iron base alloys, nickel and cobalt base alloys, and chromium and tungsten carbides are available as flux-cored wires, welding electrodes, tubular electrodes and thermal spray powders. Users of our products include mining, railroad, oil and gas, heavy construction, foundries, recycling, agriculture, sugar cane, lumber and logging, and food processing.

www.harfacetechnologies.com

Image courtesy of Hardface Technologies by Postle

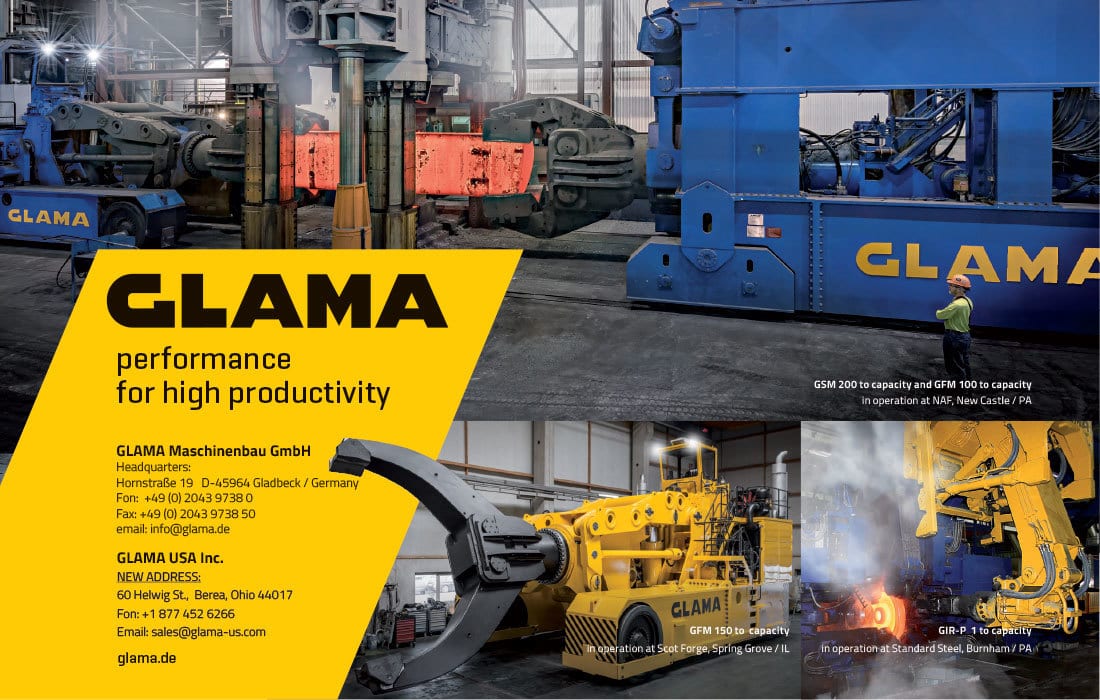

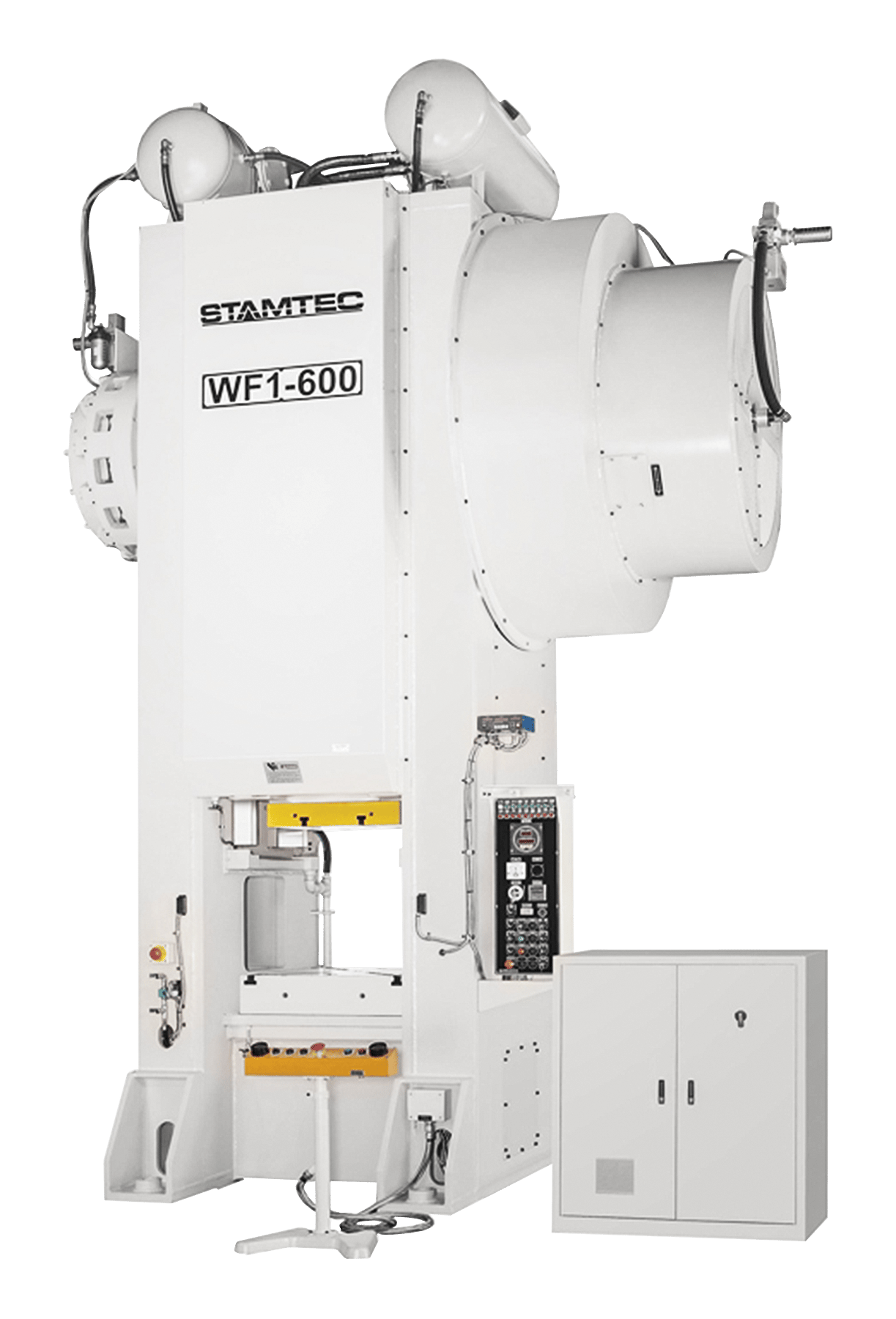

Stamtec

As one of the largest press builders in the world, Stamtec has been providing dependable, high-performance metal stamping and forging presses for more than 40 years in North America and almost 70 years worldwide. Our 72,000-square-foot sales, service, logistics and assembly facility near Nashville, Tenn., is home not only to North America's largest inventory of new presses and spare parts but also to our most important asset – our people.

Stamtec is a leader in forging press technology. Our cold and warm-hot forging presses are recognized for their durability, repeatability and ability to reduce scrap.

www.stamtec.com

Image courtesy of Stamtec

INDUSTRIALHEATING.COM | BACK TO CONTENTS | JUNE 2022