TALK

TECHNICAL

Workplace Safety in Heat Treatment

David Pye – Pye Metallurgical International Consulting

Safety in the workplace regarding heat treatment connects each and every person who works in either a captive or a commercial shop. We all have an obligation to one another to minimize the risk of accidents and injuries (no matter how minimal or extensive that injury might be).

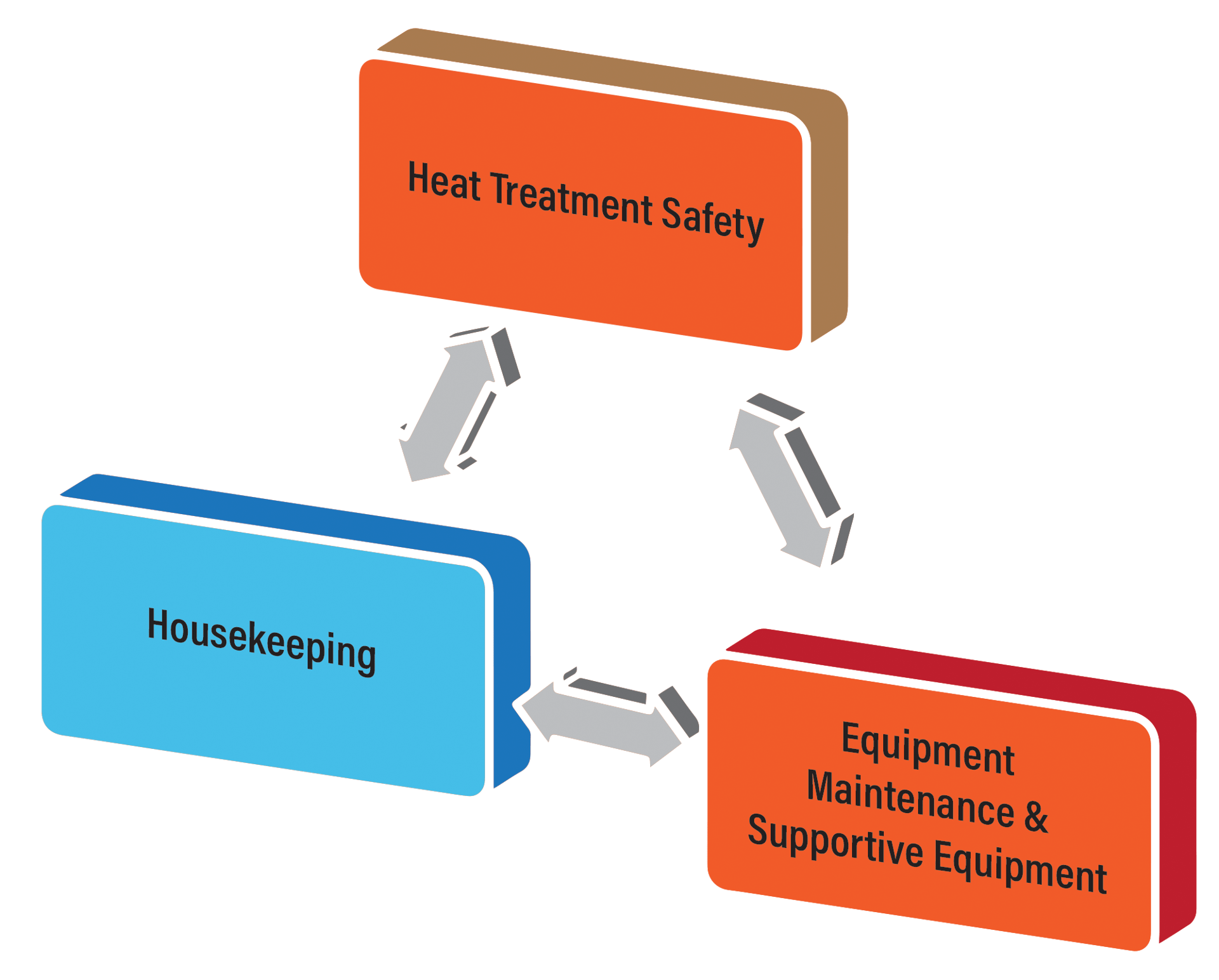

Fig. 1 shows two areas that this presentation will address.

Housekeeping

Housekeeping is a relatively easy subject to address. It is strongly suggested, especially when dealing with salt baths, that you consider a daily routine for floor cleaning. The following should also be considered:

- Demarcation lines should be painted around furnace equipment, stacking areas for baskets and trays, and unload areas.

- Demarcation lines should be painted around process-enrichment gas bottles.

- Demarcation lines should be painted around external bulk gas storage areas for easy access for delivery vehicles.

- Define the receiving area as a dispatch/pickup area.

- When operating salt baths, ensure that the salt storage area is very secure and under lock and key.

- Quenching mediums should be stored in a secure area and (if quenching oil) well away from any heat source.

- All “No Entry” and “Emergency Exit” signs should be clearly identified, including notices to follow to the nearest emergency exit.

Equipment

Quite a large number of both captive and commercial plants have integral-quench furnaces, which are used for atmosphere heat-treatment procedures such as carburizing, carbonitriding and neutral hardening. More often than not, the furnaces are filled with combustible atmospheres and an internal quench tank of specialty quench oil.

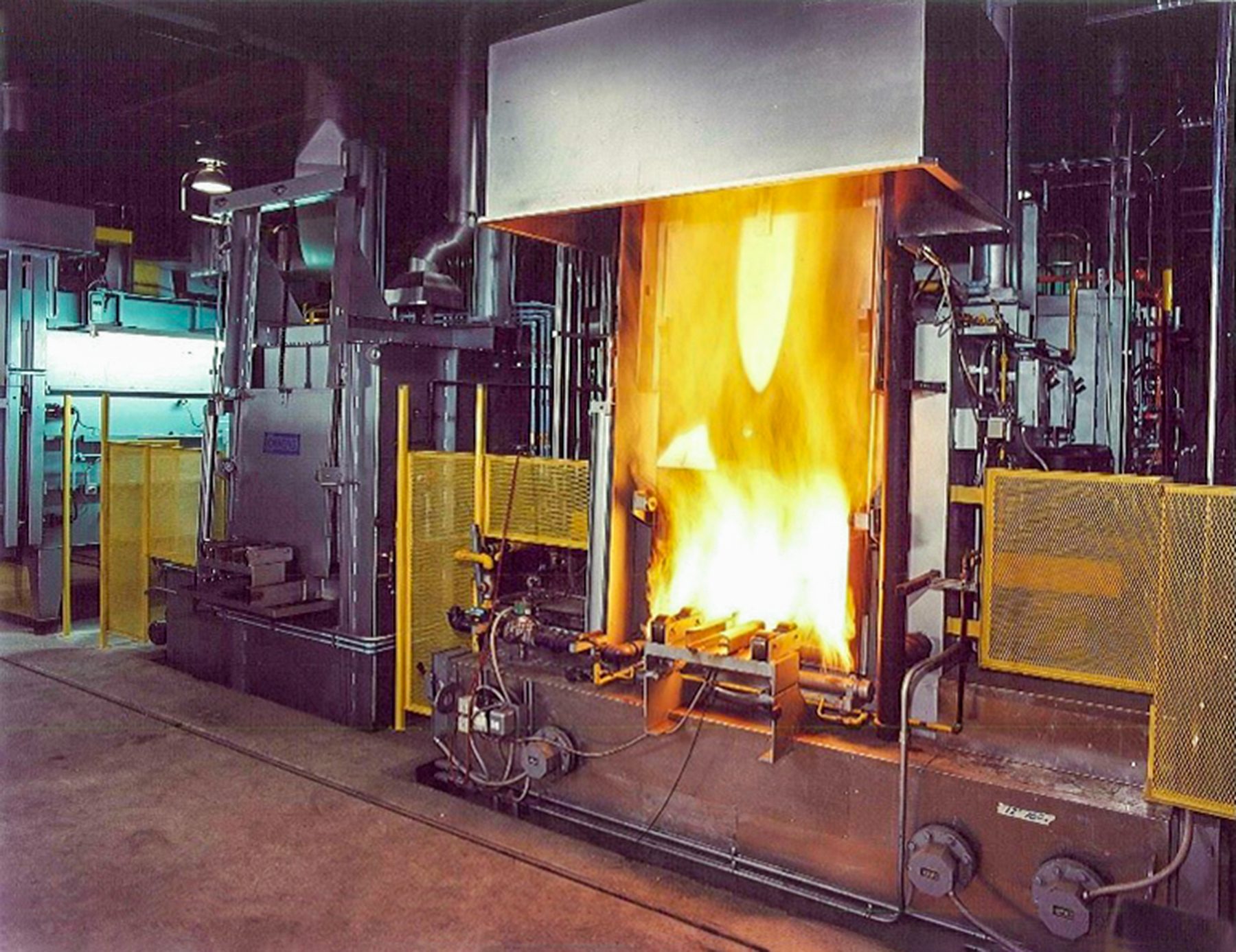

Fig. 2 is an integral-quench furnace. It can be likened to a “fire-breathing dragon” once the furnace is gassed up. The atmosphere concern also applies to continuous furnace systems, shaker-hearth furnaces and two- to four-row pusher furnaces.

The safety rules are really quite simple. However, one should follow implicitly the furnace builder’s safety and atmosphere-handling introduction into the furnace. This will be found in the manufacturer’s operational and maintenance manual. The following should also be considered:

- Do not introduce the combustible atmosphere into the furnace below 1400°F (760°C).

- Never stand directly in front of the furnace door once the furnace is gassed up with a combustible gas. If an explosion should occur, there is the potential for the explosion to blow off the furnace door.

- The integral-quench furnace will have an internal oil quench built into the unit. Ensure that the quench-medium temperature setpoint is maintained. In other words, ensure that the oil quench agitators are functional and, most importantly, that the quench-oil heat exchanger is functional and operating within the quench-medium temperature setpoint.

- Ensure that the oil quench filters (usually located on the external side of the furnace) are cleaned regularly. When the quenching procedure is in operation, fine particles resulting from microscopic debris quenching from both the workload and atmosphere are recirculating through the filters. It is recommended that a weekly filter clean is part of the maintenance routine.

- Check the functionality of the explosion caps monthly.

It is suggested that the manufacturer’s operational and maintenance manuals are held in a secured location and that at least one copy is kept in the shop, maintenance department and engineering department.

If operating an atmosphere generator, ensure that the air-to-gas is correct. Do not forget to consider potential variances in atmosphere moisture content, particularly during humid and rainy weather.

Fig. 2. An integral-quench furnace filled with process gas.

Protective Clothing and First Aid

Here are some guidelines to follow.

- Wear eye protection (goggles or a full facemask). When operating a salt bath, be sure to wear a facemask with complete head protection against salt splashes.

- Wear a full heat-resistant jacket with long sleeves for arm protection.

- Wear long-sleeved heat-resistant gloves.

- Wear appropriate foot protection with safety boots or safety shoes.

- Wear appropriate ear protection against excessive noise.

- Develop a list of specialized heat treaters who can monitor the safety aspects of the department.

- Develop a first-aid team and/or individual who has at least been trained in first aid. The first aider(s) should at least be able to deal with burns that may occur in the department.

- Develop a good first-aid kit. Ask a local doctor for assistance.

- Develop a relationship with emergency services personnel within your geographic area of operation. Visit the hospital and fire department. In addition, have an updated knowledge of responders’ telephone numbers, including the hospital, ambulance and fire department.

Fire Safety and Prevention

Here are some guidelines to follow.

- Never use water to extinguish an oil fire. It can aggravate and cause the fire to spread even farther. If possible, starve the fire of oxygen by covering it with a heat-resistant blanket and/or use a fire extinguisher.

- Have CO₂ (namely, a fire extinguisher) and gas detectors at strategic locations within the heat-treatment shop.

- Do not enter a confined space without conducting a confined-space entry meeting so that all parties fully understand their function.

- Confined-space entries by individuals without a backup is a recipe for serious potential accidents.

Conclusion

Regular furnace maintenance must be mandatory in any heat-treatment shop. The furnace and its control systems need to be regularly maintained. Without the furnace and its associated equipment, nothing is treated. Your furnace equipment are your assets!

People are also your assets. Ensure that employee safety is mandatory. Perform regular meetings within your organization via a safety committee with management to discuss and/or address potential safety issues.

Lastly, have all of the appropriate safety procedures and emergency contact numbers available and listed in a manual of standard operating procedures.

David Pye

Pye Metallurgical International Consulting

David Pye is a contributing writer. He can be contacted at 757-968-1007, pye_d@ymail.com or www.heat-treatment-metallurgy.com.

All figures/graphics provided by the author.

INDUSTRIALHEATING.COM | BACK TO CONTENTS | JUNE 2022