Vertical Tube Furnace with Stand

Thermcraft Inc.

This furnace has a vertically oriented, large cylindrical heated chamber. Inside the heated chamber is an alloy mounting bracket to suspend parts during the heating process. The furnace is mounted on a stand that incorporates pneumatic cylinders to access the heated chamber, making it easier to load and unload the furnace. The furnace is heated with heavy-duty cast plate heaters, providing good uniformity and long life.

www.thermcraftinc.com

PRODUCT SHOWCASE

SEPTEMBER 2022 | DOWNLOAD ISSUE | BACK ISSUES

INDUSTRY PRODUCTS

Pyrometer for Industrial Automation Applications

Process Sensors Corp.

Model PSC-GRF11N is a fiber-optic two-color pyrometer designed for industrial automation and research-and-development applications. Four temperature ranges are offered: 300-1100°C (572-2012°F), 350-1300°C (662-23712°F), 400-1600°C (752-2912°F) and 500-2300°C (932-4172°F). The pyrometer operates in ambient temperatures up to 250°C (482°F) and is immune to high magnetic frequencies encountered in manufacturing facilities. Independent of emissivity and spanning a range of industrial applications – including induction heating, heat treating, steel, composites and ceramics – the fast 5ms response time is ideal for quick measurement processes. A selection of variable-focus fiber-optic lenses provides small spot sizes from 0.7 mm in diameter. The non-contact infrared temperature sensor uses an integrated laser that provides precision aiming onto the center of the target. The linear temperature output signal of 4-20 mA simplifies installation into existing measurement and control systems.

www.processsensorsIR.com

Low-NOx Burner

Fives

The EcoFornax SLEx is a low-NOx burner solution for process heating and oxidation applications. Incorporating innovative air/fuel mixing technology, it is engineered to deliver a stable, compact, medium-velocity flame with low-NOx emissions. The single air and gas connections are designed to make burner installation and tuning easy. The EcoFornax SLEx has been implemented and proven in industry applications such as regenerative thermal oxidizers, air heaters, process heaters and aluminum homogenizers. It has seven burner sizes, covering a large range of capacities that extend from 0.6 to 18.6 MMBtu/h HHV, operating at nominal 40% excess air. At design capacity, the burner can operate across a ratio range from 20% excess fuel to 90% excess air, with a more expansive range at lower capacities. Its versatility and compatibility with hard refractory or fiber-wall-lined furnaces, makes the EcoFornax SLEx a simple and sustainable solution for process heating systems.

www.fivesgroup.com

Vacuum System for Industrial Processes

Leybold

The VARODRY VDi vacuum system is designed for heat-treatment, coating and drying processes. The systems consist of the air-cooled, oil-free VARODRY screw pumps, the dry-compressing Roots pumps of the RUVAC series and the VAControl CAB control for smart management of all pump processes. The VDi system can be configured by the operator according to the process requirements. This allows users to set their own vacuum capacities as needed to match the pump-down process and the pumping speed. To protect against critical gases and particles, the VARODRY VDi vacuum system can be equipped with gas ballast and purge gas. This increases service life and system availability. The integrated VAControl CAB control system, with its smart software functions, allows processes to be controlled and optimized in a user-friendly way. VARODRY VDi is suited for use in heat-treatment furnaces to improve the material properties of metals, composite applications where the resin is degassed and cryogenic pump regeneration.

www.leybold.com

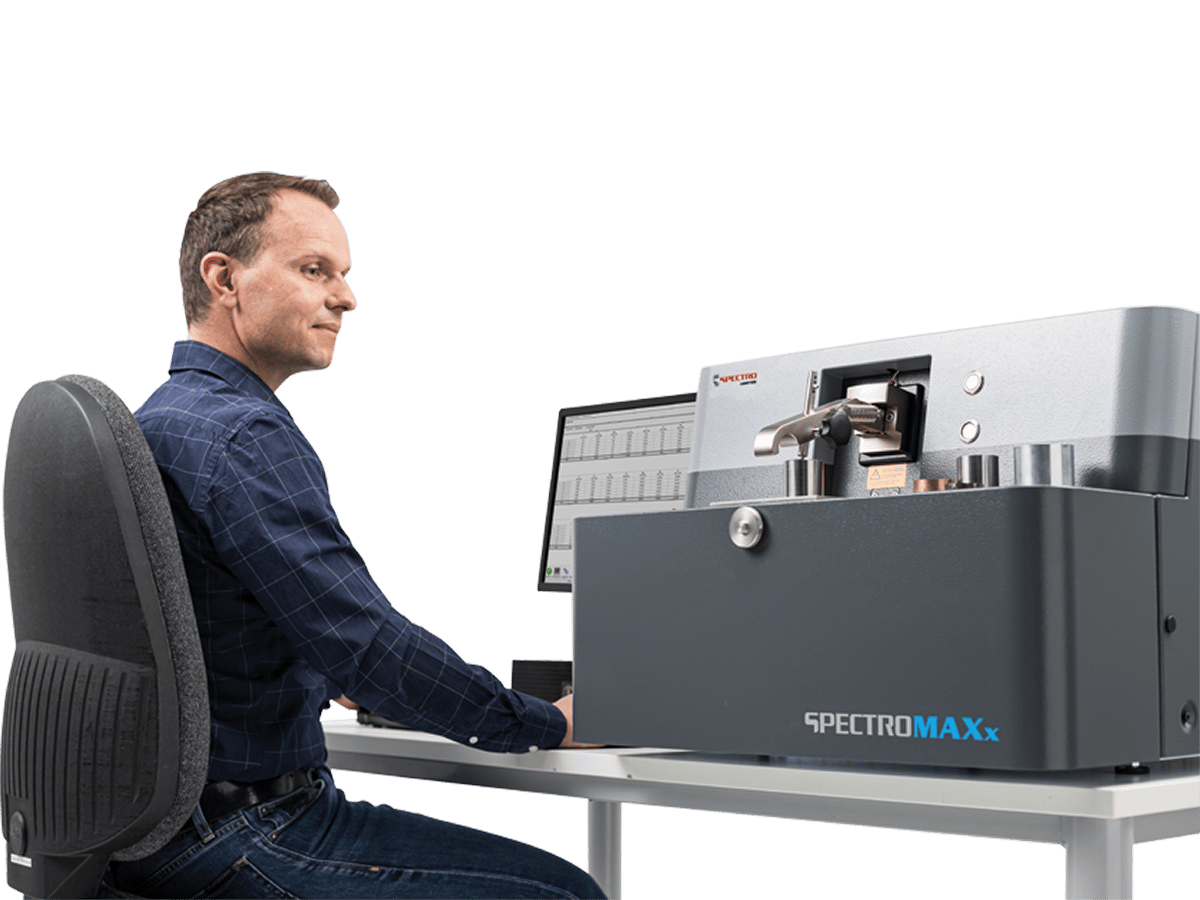

OES Analyzer for Material Control Analysis

SPECTRO Analytical Instruments

The SPECTROMAXx optical emission spectrometry (OES) analyzer is designed for fast, accurate and advanced elemental analysis in metal-producing and fabricating plants and iron and nonferrous foundries. It delivers outstanding repeatability, reproducibility and reliability in material control analyses from incoming materials to in-process testing to final quality inspections. Users can obtain ultrafast information on changing process conditions while achieving drastically reduced cost of ownership with lower consumables, and advanced diagnostics and easy maintenance prevent expensive downtime. In addition, the analyzer features SPECTRO’s proprietary iCAL 2.0 calibration logic, which requires only 5 minutes and a single sample per day. Conventional analyzers may need 30 or more minutes for standardization.

www.spectro.com