News

Safety Video Highlights Deadly Explosion, Fire at AB Specialty Silicones

“During production of an emulsion product, two incompatible chemicals were mixed. The chemicals reacted and produced flammable hydrogen gas that ignited, causing a massive explosion that killed four workers and destroyed the company’s production building.” So begins a new CSB safety video that focuses on the investigation into an explosion and fire that occurred May 3, 2019, at the AB Specialty Silicones facility in Waukegan, Ill. The incident killed four workers, destroyed the facility and caused extensive damage to nearby businesses.

The U.S. Chemical Safety Board (CSB) safety video includes an animation of the events leading up to the incident and interviews with the CSB’s chairperson and lead investigator.

In its report, the agency made recommendations to AB Specialty Silicones and reiterated recommendations to the Occupation Safety and Health Administration (OSHA) and the Environmental Protection Agency with the goal of addressing the regulatory gap covering reactive chemicals.

Image courtesy of U.S. Chemical Safety Board (CSB)

Watlow to Acquire Eurotherm from Schneider Electric

Watlow has signed an agreement to acquire Eurotherm from Schneider Electric. Terms of the transaction were not disclosed.

Eurotherm provides temperature, power and process control, measurement and data management equipment, systems, software and services for global industrial markets. The company’s headquarters are in Worthing, U.K., with core manufacturing operations in Lędziny, Poland, and a headcount of about 650 people worldwide.

“Watlow is excited to invest in this innovative product portfolio and professional team,” said Rob Gilmore, Watlow’s CEO. “Combining Eurotherm’s complementary controls technologies with Watlow’s focus on thermal systems, our shared engineer-to-engineer sales models and our focus on common markets will allow Watlow and Eurotherm to better serve all of our respective customers. We are impressed with Eurotherm’s heritage in the controls industry and strong reputation for innovation and quality, so we are looking forward to welcoming the Eurotherm team to Watlow.”

Gilmore continued, “Watlow is investing aggressively right now, including the development of our operations in Europe and Asia, to ensure we can support and respond to our customers wherever they need us. This acquisition will help us expand our presence in Europe and extend our electronics and controls capabilities globally.”

“We are very pleased to be joining the Watlow team,” said Chris Ashworth, Eurotherm’s managing director. “Watlow is a known leader in the industry, and I believe that combining our strengths will open new opportunities and create value for our customers.”

A St. Louis-based company, Watlow designs and manufactures complete industrial thermal systems.

Carousel Oven Cures Epoxy in Transmission Components

A carousel oven for curing epoxy in electrical transmission components has been shipped to a manufacturer in the energy industry.

Oven manufacturer Wisconsin Oven designed the system with a maximum temperature of 300°F (149°C) with top-down airflow. It includes a 3,400-cfm, 72 kW heating system that evenly heats parts to exacting specifications, says the company. Wisconsin Oven also provided a fully wired and tested NEMA 12 control panel.

According to Wisconsin Oven, the oven was factory assembled, adjusted and tested prior to shipment to ensure quick startup and installation.

Image courtesy of Wisconsin Oven

Plate Heat Exchanger Product Lines, Manufacturing Plant Sold

Tranter Inc. entered into an agreement with Delta T Thermal Solutions LLC, Wichita Falls, Texas, to sell certain product assets and a manufacturing plant located in Wichita Falls, Texas. The product assets are the Platecoil, Econocoil and Maxchanger heat exchanger product lines. All other Tranter products will remain exclusively available from Tranter and its authorized partners.

Tranter cites a decision to focus on its corrugated plate technologies such as its Superchanger, Novusbloc and Supermax as a driver for the sale. Tranter has opened a new facility and innovation center in Houston, Texas, and it will continue to provide customized thermal applications.

Industrial Oven Used for Multiple Applications in Nuclear Industry

A custom industrial oven designed and manufactured for a company in the nuclear supply industry will be used for multiple applications. Lewco Inc. designed and manufactured the electrically heated, top-load oven, which has a maximum temperature of 900°F (482°C).

According to Lewco, the batch oven is equipped with a bottom-mounted heater box and an electrically actuated top-load door. It has a heat capacity of 36 kW, and a 700-cfm circulation fan delivers horizontal airflow evenly throughout the workspace. The oven also is equipped with a structurally reinforced floor to support up to 600 lb.

Oven controls include a programmable ramp/soak temperature controller and a redundant high limit controller. The main process controller includes Ethernet communications to allow remote monitoring of temperature and alarms.

Image courtesy of Lewco Inc.

Grand Jury Indicts 6 Managers on Counts Related to Didion Combustible Dust Explosion

A federal grand jury indicted the operator and six management officials of a Cambria, Wis., corn mill where a May 31, 2017, combustible dust explosion killed five workers and injured 15 others. The nine criminal counts include two counts related to willful violations of federal workplace safety standards for grain handling.

Handed down by a grand jury in the U.S. District Court for the Western District of Wisconsin in Madison on May 11, the indictment of Didion Milling Inc. and its current and former managers includes counts of document falsification in contemplation of a U.S. Department of Labor, Occupational Safety and Health Administration investigation and obstructing the federal OSHA investigation. The indictment also charges the company and the six officials falsified entries in a cleaning logbook, which involved matters under the jurisdiction of OSHA.

The indictment alleges that Didion Milling willfully violated two federal safety standards in the Occupational Safety and Health Act — by failing to develop and implement a written program to effectively prevent and remove combustible grain dust accumulations, and by not installing venting or suppression on a dust filter collector to prevent an explosion — thereby, causing the deaths of five employees due to the combustible dust explosion on May 31, 2017.

The grand jury indictment also includes the following allegations:

- Didion Milling and four employees — Derrick Clark, vice president of operations; Shawn Mesner, former food safety superintendent; and Anthony Hess and Joel Niemeyer, former shift superintendents — conspired to commit fraud by agreeing to take deceptive measures to conceal the failure to adhere to food safety procedures at the mill.

- Didion Milling, Clark, Mesner, Hess and Niemeyer — along with James Lenz and Joseph Winch, former environmental coordinators for Didion — conspired to commit federal offenses to conceal violations and unsafe conditions from auditors and government agencies.

- Hess, Clark and Didion obstructed justice by providing false and misleading testimony after the explosion to OSHA about their knowledge of combustible dust hazards at the mill.

- Former Didion Milling shift superintendents Michael Bright and Nicholas Booker pleaded guilty previously to making false entries in Didion Milling's cleaning logbook and false entries in the baghouse log, which involved matters within the jurisdiction of OSHA and EPA, respectively.

Based in Sun Prairie, Didion Milling Inc. has been in operation since 1972. The company operates a corn milling and biofuels facility in Cambria and production facilities in Markesan and Johnson Creek.

Heraeus Acquires PET Recycling Company

Heraeus Holding GmbH invested substantial equity to take a majority stake in perPETual Technologies, a PET recycling company. To drive global expansion under one brand, Heraeus renamed the company Revalyu Resources GmbH (Revalyu).

Polyethylene terephthalate (PET) is the most common thermoplastic polymer of the polyester family. It is used in textiles, packaging containers for liquids and foods, thermoforming for manufacturing and other consumer products.

According to Heraeus, Revalyu has developed an environmentally sustainable depolymerization technology to recycle post-consumer PET bottles into sustainable esters (monomers), which is the base chemical building block for anything polyester based. Revalyu’s polymer can be used to manufacture sustainable PET products.

The company currently produces filament yarns for the textile industry in its manufacturing facility in Nashik, India.

Image courtesy of Heraeus

Refrigerated Trailer Donated to Aid Food Banks

A refrigerated trailer has been donated to the Northeast Washington (N.E.W) Hunger Coalition. The food pantry plans to put it to immediate use.

The refrigerated trailer, designed and manufactured by Colmac Coil Manufacturing, is part of the Cool Pup program from N.E.W., which helps solve the challenge of transporting fresh produce from farms to 17 food pantries supported by N.E.W. Hunger Coalition and their community partners. The goal of the Cool Pups program is to provide fresh and healthy produce to Northeast Washington community members experiencing food insecurity.

Colmac designed and manufactured an enclosure with industrial-grade insulated panels, with similar construction as its A+P “mini penthouse” evaporator product line.

Image courtesy of Colmac Coil Manufacturing

Cooling Equipment Manufacturer Raises $65,000 for Charity During Golf Tournament

An annual charity golf tournament hosted by SPX Cooling Technologies Inc., Overland Park, Kan., on May 19, raised more than $65,000 for two organizations. Literacy KC, a Kansas City-based community for adults and families to improve literacy skills and enhance their quality of life, and the Kansas City Professional Chapter of Engineers without Borders USA, a nonprofit organization that builds a better world through engineering projects that empower communities, will benefit from the fundraiser.

The golf tournament at Sycamore Ridge Golf Course in Spring Hill, Kan., included 140 golfers and dozens of volunteers from SPX Cooling, Literacy KC and EWB-USA. SPX employees, suppliers, sales representatives and supporters played an 18-hole “scramble-style” tournament. Additional challenges were available throughout the course such as longest drive, longest putt and closest to the pin. A silent auction and raffle following the tournament added to the event donations. All net proceeds from the tournament will be shared by Literacy KC and EWB-USA, says SPX Cooling Technologies.

“The tournament was a great success and we owe that to our generous sponsors, participants and volunteers for helping make it happen,” commented Ankush Kumar, the president of SPX Global Cooling. “Without them we wouldn’t have been able to raise the money we did for these well-deserving organizations.”

SPX Cooling Technologies began holding the annual charity golf tournament in 2014 and has since contributed more than $300,000 to nonprofit organizations. The 2022 tournament is the first since 2019, and it coincides with the centennial of the Marley brand.

Screw Compressor Maker Adds Ammonia Models to Line

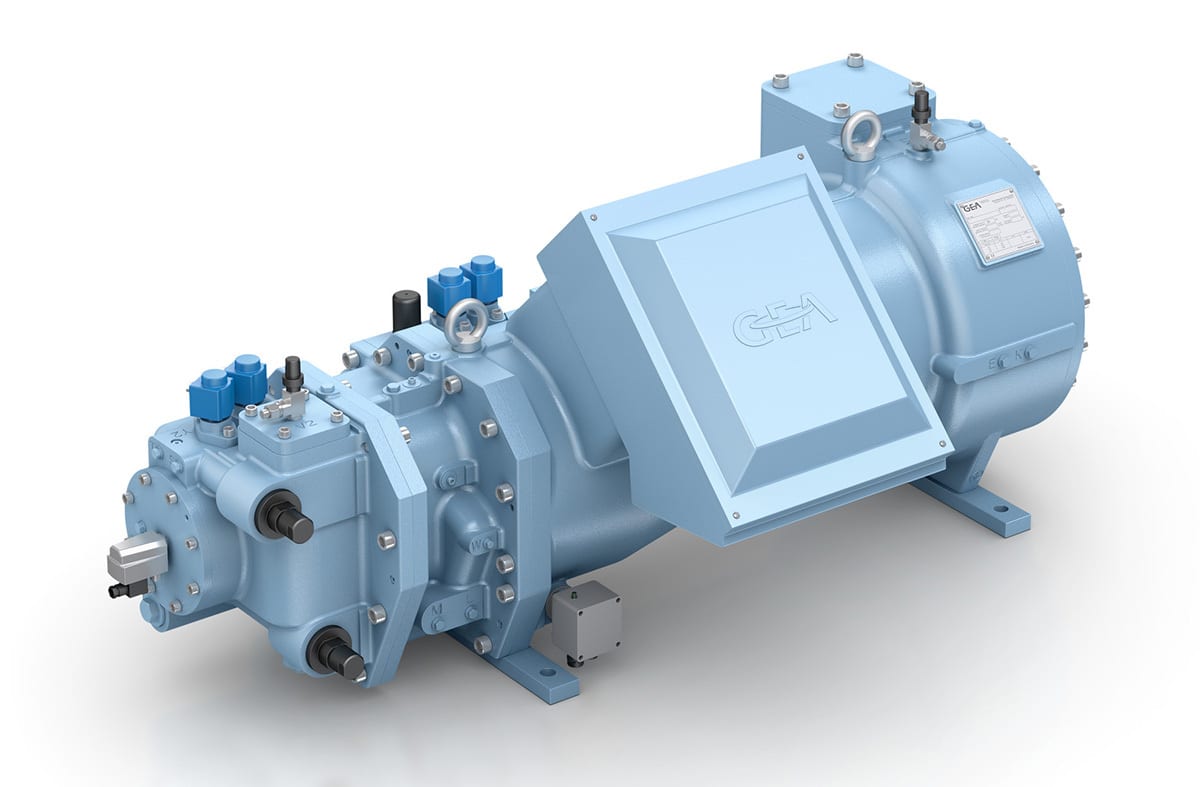

Two screw compressor models and a semi-hermetic screw compressor package will be part of a new product launch by GEA Heating & Refrigeration Technologies in the second quarter.

CompaX models 350 and 400, with a flow volume of 321 and 372 m³/h (at 2,940 rpm) respectively, extend from GEA Heating & Refrigeration Technologies’ semi-hermetic screw compressor series from larger to medium and also smaller capacity requirements. They use ammonia, a natural refrigerant, and their compact design saves space, says the company.

The GEA Grasso X semi-hermetic screw compressor offers refrigeration capacities from approximately 200 to 1,900 kW.

Image courtesy of GEA Heating & Refrigeration Technologies

Ceco Environmental Acquires Water Treatment Systems Supplier

Compass Water Solutions Inc. — a supplier of membrane-based industrial water and wastewater treatment systems in Tustin, Calif. — was acquired by Ceco Environmental Corp. for $12.5 million.

The transaction adds another company to Ceco’s portfolio of industrial water technologies brands. According to the company, it expands Ceco’s addressable industrial water technology market by more than $250 million with expected growth rates above 6 percent CAGR through 2025 for industrial oily-water and seawater reverse osmosis applications.

Compass’ installed base of over 8,000 systems worldwide, which creates a robust aftermarket parts and services business, was noted as a benefit of the acquisition. “Compass adds critical engineered solutions and an experienced leadership team to our growing industrial water capabilities, and we are excited to welcome them to the Ceco organization,” said CEO Todd Gleason.

CECO has completed three industrial water acquisitions in 2022. In April, it acquired substantially all of the assets of Index Water, expanding its water treatment solutions portfolio serving the Middle East region. In March, it acquired industrial flow control company GRC as a part of its push into the water, stormwater and wastewater markets.

Ice Producer Settles with EPA for Ammonia Violations

An ice producer in New Bedford, Mass., agreed to a $170,000 settlement with the Environmental Protection Agency for breaches of safety regulations in the use of its ammonia refrigeration system.

Crystal Ice Co. is a supplier of ice for the fishing industry in and around New Bedford. The facility uses up to 22,000 pounds of anhydrous ammonia in its refrigeration system. Anhydrous ammonia can be dangerous when released into the environment.

An ammonia release at the Crystal Ice facility occurred in April 2018 and triggered an EPA inspection of the refrigeration system. The EPA’s inspection led to the discovery of multiple violations of the Clean Air Act’s Risk Management Plan regulations, which are designed to prevent accidental releases of substances that can cause serious harm to the public and the environment from short-term exposures and to mitigate the severity of any releases that do occur.

Some of the alleged violations included the failure to comply with requirements to compile written process safety information and comply with recognized and generally accepted good engineering practices; failure to fully comply with process hazard analysis requirements; and failure to adequately train employees.

The settlement imposes a civil penalty of $170,000 and requires that the company come into compliance with risk management plan regulations.

Image courtesy of Hans/Pixabay

Coil Technology Expands Dry Operation of Fluid Cooler

SPX Cooling Technologies Inc. incorporated a proprietary Aero-X coil technology into its induced-draft, closed-circuit DT fluid coolers. The Aero-X tube profile maximizes thermal capacity per coil row, says the company.

Dry operation is extended for longer periods with switch point temperatures up to 10°F higher than other similar closed-circuit cooling towers, according to the manufacturer. Depending on climate, operators can gain up to 15 to 20 percent more incremental annual hours in dry mode, with 3,000 gal/ton and $40/ton annual water savings per ton of cooling achievable in many areas.