Products

the latest products to help you improve your manufacturing process

InnovMetric PolyWorks 2024

InnovMetric announces the launch of PolyWorks 2024. This enterprise solution sets up a digital thread that lowers the cost of scaling up the use of 3D measurement data by deploying a universal 3D metrology platform and delivering 3D measurement data to engineering and manufacturing teams in real-time. The PolyWorks digital ecosystem accelerates the design, development, and validation of products and manufacturing processes. It also controls the quality of individual pieces and assembled products, and helps resolve manufacturing issues as soon as they occur.

This new PolyWorks release significantly lowers the costs related to learning and operating 3D metrology software, managing large point cloud data files, and leveraging 3D measurement data within third-party reporting and analysis solutions:

- The user interfaces of the PolyWorks universal 3D metrology platform have been re-engineered to let users perform inspection tasks and discover new tools intuitively, access frequently used tools more directly, and quickly find the functionalities that apply to selected objects. PolyWorks 2024 allows new users to learn and master basic workflows more easily, while seasoned users can strengthen their skills by exploring new tools at their fingertips.

- PolyWorks 2024 can manage vast amounts of 3D measurement data efficiently by using cloud storage, which is cost effective and delivers benefits such as instantaneous storage space increase and data file replication across multiple data centers.

- PolyWorks now offers plug-ins that interconnect its data management system to the Excel and Power BI industry-standard reporting and analysis solutions from Microsoft. Manufacturing organizations will appreciate the simplicity of being able to rapidly inject smart 3D inspection data into their favorite reporting tool, instead of having to train their internal experts at considerable cost on a third-party solution.

The PolyWorks|Inspector™ solution helps reduce time-to-market by measuring, controlling, and analyzing 3D dimensions at every stage of the manufacturing process. With version 2024, InnovMetric delivers major gains in efficiency through its re-engineered user interfaces. Users can now:

- Perform inspection tasks and discover new tools intuitively, thanks to a new ribbon menu and an improved interface widget organization that offers a more logical workflow

- Access frequently used tools more directly, thereby reducing mouse movements and clicks

- Quickly find the functionalities that apply to selected objects by accessing a contextual tab or a simplified contextual menu

PolyWorks|Inspector 2024 also offers new high-value tools and workflows:

- Surface datum features within datum reference frames

- Contextual control views to analyze surface deviations in multiple alignments and inspect dimensional controls in multiple coordinate systems

- CADless inspection workflows on CNC CMMs

The PolyWorks|PMI+Loop™ Model-Based Definition solution allows manufacturing organizations to manage all the dimensional controls defined by the design and manufacturing teams within their native CAD platform. Version 2024 lets users add specialized supplemental information to characteristics, such as criticality classifications, quality plan requirements, and revision numbers. Once defined within their CAD platform, characteristic augmenters may then be consumed by downstream applications, such as PolyWorks|Inspector.

The PolyWorks|DataLoop™ data management solution stores 3D measurement data on central servers and digitally interconnects all the people who capture or need access to 3D measurement information. Version 2024 now leverages the full benefits of cloud storage. Manufacturing organizations can:

- Set up a highly scalable infrastructure that adapts instantaneously to storage needs

- Replicate data files automatically across multiple data centers to ensure reliability

- Deploy a cost-effective storage solution without compromise

Security policies allow manufacturing organizations to control who has access to data and what can be done with it. Version 2024 allows PolyWorks|DataLoop users to:

- Implement sound data access policies by assigning distinct storage spaces to different departments, business areas, or external suppliers

- Define security policies efficiently by creating new policies from existing ones and enriching them with specific permissions

The PolyWorks|DataLoop Web interface allows users to review 3D measurement results within a standard Web browser through an extensive set of standard and special-purpose widgets. With version 2024, users can now:

- Display the 3D measurement results of one or multiple pieces horizontally

- Create an unlimited number of widgets within a dashboard

- Leverage Excel’s extensive mathematical and charting functionalities

PolyWorks|ReportLoop™ is an interoperability solution that integrates inspection data into Microsoft Excel for reporting and advanced analysis. Version 2024 now allows manufacturing organizations to interconnect their PolyWorks|DataLoop server to Excel. Users have access to a search engine to quickly find sources of data plus user-friendly tools to inject smart 3D inspection data into their spreadsheets. Excel spreadsheet cells remain dynamically linked to the data they contain through formulas.

Version 2024 also marks the debut of a new PolyWorks|ReportLoop for Power BI solution. PolyWorks’ Power BI connector allows retrieving data from a PolyWorks|DataLoop server and leveraging the query editor to process the imported data and display it using Power BI’s powerful visualization tools.

InnovMetric

innovmetric.com

Creaform Portable HandySCAN 3D Scanner

With the most accurate BLACK Series yet, made possible through a new certification and the addition of key features, as well as a complete redesign of the SILVER Series, Creaform fulfills the evolving needs of metrology professionals and designers looking to improve their quality control and product development processes.

Creaform, a business of AMETEK, Inc., unveils its next-generation scanners with the introduction of the HandySCAN BLACK+™️|Elite, and the complete redesigned of the HandySCAN SILVER™️ and HandySCAN SILVER™️|Elite. These latest iterations of the BLACK and SILVER Series promise superior precision as well as enhanced user experience.

The new HandySCAN BLACK+™️|Elite provides a superior level of accuracy through the use of the Accu+ Kit, enabling the user to confidently rely on an optimized volumetric accuracy of 0.020mm+0.015mm/m. Boasting the new Flex Volume, it provides a greater scanning measurement volume, and allows for an adjustable scanning distance that is simple to use, from near (200 mm) to far away (700 mm). Leveraging its newly acquired certifications, the BLACK Series also ensures precision and measurement reliability through its VDI/VDE 2634 part 3 and ISO 10360-based sensor acceptance tests in its ISO/IEC 17025-2017 accredited laboratories, underscoring Creaform’s commitment to rigorous performance evaluation and quality assurance.

As for the newly revamped SILVER Series, it emerges as a transformative tool in product development. With a new ergonomic aesthetic, its heightened resolution catering to intricate details, versatile scanning capabilities accommodating various surface types, and user-friendly design accessible to all, the SILVER series still offers the most value for money. Without compromising affordability, it integrates the cutting-edge advancement of the BLACK Series, leveraging a proven design, compatibility with the recently launched Automation kit and benefiting from exceptional customer service and worldwide support.

As Simon Côté, product manager at Creaform, emphasizes, “We are more than a simple solution provider, we partner with companies to improve our products based on their feedback, ensuring that they get the most out of our 3D scanning technologies and software and get to experience innovation firsthand.” He then adds that “with these enhancements in the BLACK and SILVER Series, we provide a complete development path from beginner to expert, in a single lineup; the same that made us pioneers in self-positioning 3D laser scanner.”

Creaform, a business of AMETEK, Inc.

creaform3d.com

Teledyne MicroCalibir Long Wave Infrared Compact Thermal Camera Core

Teledyne DALSA, a Teledyne Technologies company, announced a radiometric version of its MicroCalibir™ Long Wave Infrared (LWIR) compact camera platform that delivers accurate temperature measurements of +/-2°C or +/-2%.

Developed and manufactured in Canada, the small and lightweight MicroCalibir platform is the result of the latest advances made by Teledyne DALSA’s integration of their in-house 12 μm microbolometer pixel technology with a deep-ADC ROIC circuit. This radiometric version provides absolute temperature information of sub-50 mK NETD while simultaneously delivering intrinsic dynamic range > 650°C, making it ideal for a range of applications in industrial process monitoring and maintenance, security and surveillance, and search and rescue.

This MicroCalibir camera has a resolution of 640 x 480 pixels (VGA) or 320 x 240 pixels (QVGA) and is available with a camera parallel, USB, or MIPI CSI2 video interface. For easier integration, the camera core is supplied without a housing and with an M24 in VGA format or M18 optical interface for QVGA video format. It has the same SWaP optimized format as the current MicroCalibir, which measures only 21 mm x 21 mm x 22.7 mm with lens mount and electronics boards, and weighs less than 20 grams, with no sacrifice on NETD levels or on image quality performance.

Worldwide technical support is available to assist with integration and to implement any custom parts that might be required. Specific LUTs have also been developed to assist in its successful integration.

Later this year, this radiometric development will also be implemented in the next release of the Calibir GX series cameras.

Teledyne DALSA

https://www.teledyneimaging.com/en/home/

IDS NXT Malibu Camera

IDS expands its product line for intelligent image processing and launches a new IDS NXT malibu camera. It enables AI-based image processing, video compression and streaming in full 4K sensor resolution at 30 fps – directly in and out of the camera. The 8 MP sensor IMX678 is part of the Starvis 2 series from Sony. It ensures impressive image quality even in low light conditions and twilight.

Industrial camera with live AI: IDS NXT malibu is able to independently perform AI-based image analyses and provide the results as live overlays in compressed video streams via RTSP (Real Time Streaming Protocol). Hidden inside is a special SoC (system-on-a-chip) from Ambarella, which is known from action cameras. An ISP with helpful automatic features such as brightness, noise and color correction ensures that optimum image quality is attained at all times. The new 8 MP camera complements the recently introduced camera variant with the 5 MP onsemi sensor AR0521.

To coincide with the market launch of the new model, IDS Imaging Development Systems has also published a new software release. Users now also have the option of displaying live images from the IDS NXT Malibu camera models via MJPEG-compressed HTTP stream. This enables visualization in any web browser without additional software or plug-ins. In addition, the AI vision studio IDS lighthouse can be used to train individual neural networks for the Ambarella SoC of the camera family. This simplifies the use of the camera for AI-based image analyses with classification, object recognition and anomaly detection methods.

IDS Imaging Development Systems GmbH

https://www.ids-imaging.com

Morehouse Instrument Automated Force Calibration System

The Automated Force Calibration System can be purchased as an upgrade or with any existing Morehouse Universal Calibrating Machines or Scale Calibration Press. It improves accuracy, repeatability, and reproducibility. It simplifies cal-tech training and can increase productivity by as much as 75 percent. The Morehouse Automated Force Calibration System stands as an exclusive, proprietary solution meticulously crafted for seamless integration with Morehouse hydraulic rams (Part of the Morehouse UCM), accommodating pressures up to 4500 PSI—capabilities that outshine conventional hydraulic and automated controls limited to 3000 PSI. The automation control system is purpose-built to interface exclusively with Morehouse UCMs, drawing power from a standard 120V AC outlet, eliminating the need for additional outlets or structural modifications.

Morehouse Instrument Company

https://mhforce.com/product/automated-force-calibration-systems/

Ximea Ultraviolet Camera Models

As part of its xiLAB initiative, XIMEA expands the offer of Ultraviolet cameras with MX081 models.

Within the realm of modern technology, cameras have progressed from mere devices capturing visible light to sophisticated tools divulging concealed facets of the electromagnetic spectrum. One of the innovations is the UV camera, delving beyond human visual perception, and unlocking a realm of information that was previously unattainable.

UV cameras operate on the principle of capturing ultraviolet (UV) light, an unseen segment of the electromagnetic spectrum bearing insights into various phenomena, from forensics to astronomy. UV cameras function by capturing the UV light that objects reflect or emit. They employ specialized sensors or filters detecting and recording UV wavelengths. Unlike traditional cameras relying on visible light, UV cameras integrate components designed to prevent contamination from visible and infrared light sources, ensuring that captured images are primarily influenced by UV radiation.

The MX081 model features Sony's IMX487 sensor, renowned for its superior image quality, low noise, and high sensitivity. The camera delivers exceptional performance and reliability, leveraging Sony's advanced sensor technology, ensuring consistent results in demanding environments. With a spectral range extending from 200 to 400 nm, XIMEA's MX081 model of UV camera captures UV radiation with exceptional sensitivity and accuracy. This specific wavelength range allows for the detection of subtle variations in UV reflectance and fluorescence, enabling enhanced analysis and visualization of target materials and substances.

Equipped with a resolution of 8.1 megapixels (2856 x 2848 pixels), the camera delivers sharp, detailed images with precise pixel-level clarity. With a frame rate of 59 frames per second (FPS), the MX081 camera enables smooth, real-time imaging of dynamic scenes and fast-moving objects. This high frame rate is ideal for applications requiring rapid image capture, such as machine vision, motion analysis, and quality control in manufacturing processes. Measuring just 26 x 26 millimeters, it boasts a compact and lightweight design, making it versatile and easy to integrate into a wide range of systems and applications.

Whether mounted on drones for aerial surveys, incorporated into handheld devices for field inspections, or installed in laboratory equipment for scientific research, XIMEA offers flexibility without compromising performance.

The extraordinary range of applications, the unmatched features of a UV camera and the broad fascination of scientists to laypeople suggest that the future promises even more evolutionary discoveries in the world of ultraviolet imaging.

UV cameras are beneficial in a widespread field of applications - operating through various wavelenth ranges like UVA (315-400 nm), UVB (280-315 nm), UVC (100-280 nm).

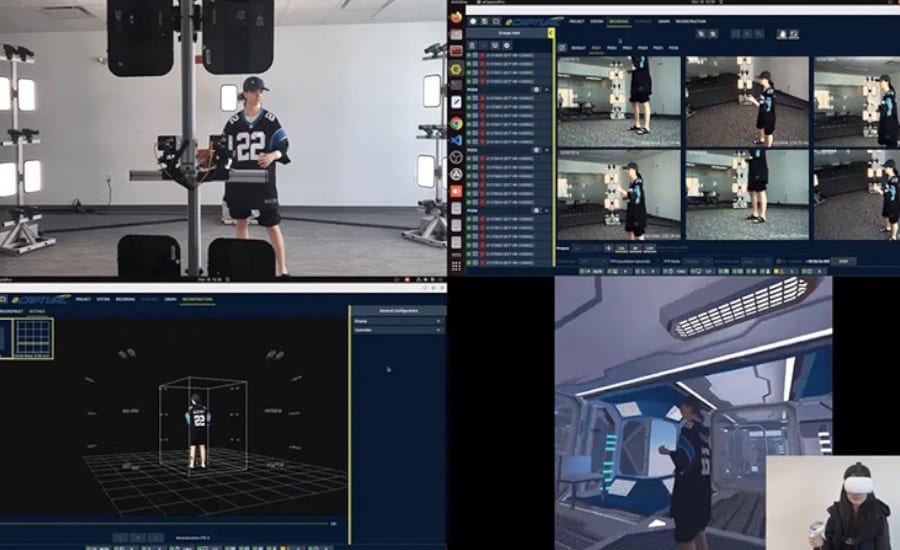

Emergent Vision Technologies Real-Time 3D/4D Reconstruction Software

Emergent Vision Technologies is introducing its expanded real-time 3D/4D reconstruction capabilities within eCapture Pro software.

eCapture Pro software offers an intuitive drag-and-drop interface for setting up, configuring, and running multiple volumetric cameras, servers, storage, GPUs, and other system components without the need for sophisticated vision expertise. Previously, Emergent’s software first needed to record volumetric camera data to storage before it could perform post-3D reconstruction of the video. Now, proprietary algorithms enable eCapture Pro software to generate volumetric video in real time on a single server, allowing more immediate engagement and immersion in captured events as they unfold.

During NAB 2024, Emergent will showcase the powerful new capabilities of its eCapture Pro vision software for generating volumetric video data in real-time. Emergent invites visitors to enter a high-quality virtual space reconstructed within a 7-ft. tall cylinder with a 3-ft. diameter. The space is reconstructed from volumetric data captured by 36 12-MP 10GigE cameras running at 30 fps. All images are transferred directly to a single NVIDIA RTXA6000 GPU via Emergent’s GPUDirect technology.

Emergent Vision Technologies

www.emergentvisiontec.com

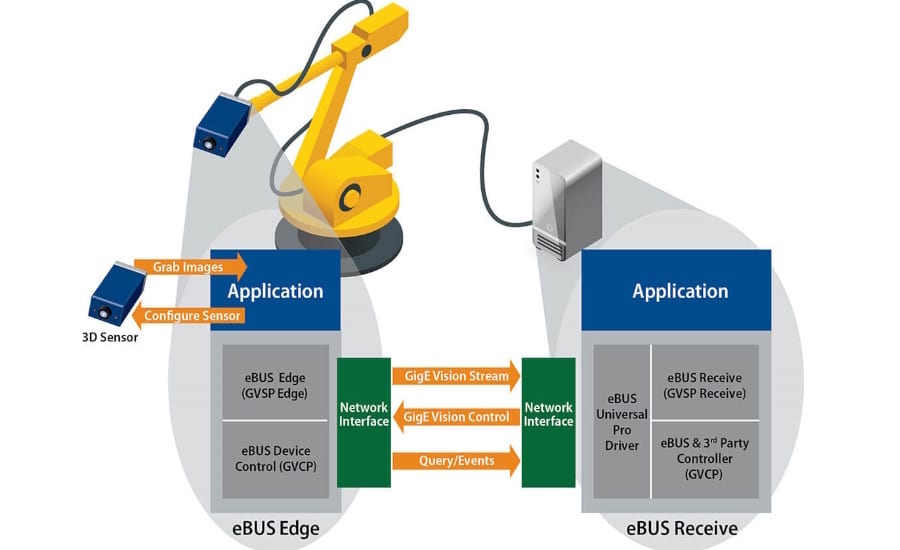

Pleora GigE Vision Software with Expanded eBUS Edge Platform

Pleora Technologies is expanding its eBUS Edge GigE Vision software transmitter solution with feature-based licensing tiers to help designers meet performance and cost demands as new 3D cameras, sensor-based imaging devices, and embedded and IoT products are deployed in machine vision applications.

eBUS Edge converts imaging solutions and embedded devices to fully compliant GigE Vision, GenICam devices without investing in any additional hardware. By adding eBUS Edge to a CPU’s software stack, devices support GigE Vision compliant image transmission, can respond to control requests from a host PC, and integrate with off-the-shelf machine vision processing. The GigE Vision software transmitter has been designed into 3D and smart cameras and data transmission systems for medical imaging.

Canada-based camera manufacturer Labforge has designed eBUS Edge into its Bottlenose™ family of high-resolution smart cameras for automation, robotics, and defense applications. Available in both a stereo and monocular version, Bottlenose includes on-camera AI processing, feature point detection and matching, up to 4K depth resolution, and a powerful ISP to navigate complex lighting situations.

For 3D inspection, eBUS Edge converts 3D images and data into GigE Vision and GenICam compliant time-stamped data that is transmitted with associated metadata over low-latency Ethernet cabling. Data from multiple sensors, including 1D and 2D images, can be synchronized and transported in parallel using multiple streams. To simplify image processing, the 3D data is received, analyzed, and displayed using off-the-shelf machine vision processing. In comparison, competing solutions require proprietary approaches for 3D data transmission and limit processing choice.

For embedded applications, eBUS Edge enables designers to develop small form-factor GigE Vision imaging and sensor devices that are easily networked and integrated with machine vision processing solutions. In these multi-sensor applications, embedded processing can make local decisions, transmit processed data to other sensors or standard vision processing solutions, and respond to control requests from a host controller over a low latency GigE Vision Ethernet connection.

New feature-based licensing tiers for eBUS Edge supporting multi-part, multi-stream 3D/2D/1D performance requirements for high-value imaging and sensor platforms and single-stream 2D/1D transmission for price-sensitive cameras, embedded platforms, and IoT devices are now available. The software solution is designed for both Intel and ARM architectures and is compatible with all sensor and camera types.

Pleora

pleora.com/ebus-edge