Acrylic finish coats from MuleHide extend the lives of low-slope roofs, providing a seamless, waterproof and weathertight layer of protection that stands up to the elements. Part of MuleHide’s acrylic roof coating system, they can also dramatically lower rooftop temperatures, reducing cooling costs. A-310 Finish and A-300 Finish are compatible with a wide variety of common roof substrates. A-310 is also ideally suited for use on sprayed polyurethane foam (SPF), employing a highly flexible acrylic polymer that accommodates the thermal expansion and contraction of SPF roofs. Both finish coats resist dirt pick-up to maintain the roof’s aesthetics and energy efficiency after weathering.

For more information, visit mulehide.com.

PRODUCT FOCUS

SPONSORED BY

Ecodur1 Cool Roof Coating from Castagra is a fiber-reinforced premium cool roof coating with superior adhesion and impact resistance. With no maximum thickness and a low-sag formula, Ecodur1 is a one-coat solution on most substrates, generally requiring no base or topcoat. Ecodur1 is also odorless, 100% solids, and has lifetime repairability. Ecodur1 is energy efficient and highly reflective, meeting the requirements of California Energy Commission (CEC) Title 24, and is listed by the CRRC. Ecodur1 is VOC-free, non-toxic and made of sustainable materials, making it the environmentally friendly choice as well as the top performing.

For more information, visit castagra.com.

GacoBase U95 is a two-component, bio-based urethane base coat that simplifies roof restoration and serves as a spray foam alternative for encapsulating built-up gravel (BUR) systems. It eliminates the need for bleed-blocking primers, streamlining prep and boosting long-term performance. Ideal for asphaltic, single-ply, and previously coated roofs, U95 delivers exceptional tensile strength and durability in high-traffic, impact-prone areas. Its low-VOC, castor oil-based formula reduces reliance on petroleum materials and meets compliance in all 50 states. GacoBase U95 can be topped with any GacoFlex coating for a seamless, fully integrated restoration system.

For more information, visit gaco.com.

Storm Breaker HB Silicone by BITEC is a high-build, single-component silicone roof coating engineered for superior waterproofing and UV protection. Ideal for restoring aged roof systems, it delivers outstanding durability and ponding water resistance, extending the life of commercial roofs. Storm Breaker HB Silicone forms a seamless, breathable membrane that withstands harsh weather conditions while reflecting heat to improve building energy efficiency. With high solids content and excellent adhesion across multiple substrates, it’s a top choice for long-term roof maintenance. This environmentally friendly solution ensures reduced application time and low VOC compliance for sustainable building practices.

For more information, visit bitec.com.INSIDE THE METAL SPECIAL SECTION

Why tear off when you can restore? A direct-bond optimized, heavy-bodied elastomeric coating, SMARTCOAT 400 High Performance Acrylic Roof Coating is a tough, durable roof restoration solution. This product achieves excellent bond strength to all common roof substrates, including metal, single-ply, built-up, and modified bitumen roofs. What’s more, SMARTCOAT 400 has extremely high elastomeric properties, making it a tough and durable solution to seal roof surfaces in all North American climates, prolong roof service life, and reduce interior building temperatures and associated cooling costs. CertainTeed’s SMARTCOAT roof restoration products numbers align with the proper application sequence:

• 100 Series: Clean

• 200 Series: Prime/prepare surfaces only as needed

• 300 Series: Seal

• 400 Series: Coat

For more information, visit certainteed.com.• 100 Series: Clean

• 200 Series: Prime/prepare surfaces only as needed

• 300 Series: Seal

• 400 Series: Coat

TECNOCOAT is a revolutionary line of high-performance, monolithic waterproofing and traffic coating systems. Developed and tested to withstand the most extreme environments, TECNOCOAT offers exceptional durability and fast drying times (foot traffic-ready in minutes) and superior chemical resistance for long-lasting performance in demanding environments. Its versatility means it can be used in a wide range of applications, including below-grade foundation applications, plazas, parking decks, and secondary containment areas. A fully bonded, monolithic membrane provides superior protection against water infiltration. Ease of use with both spray-applied and hand-applied options. The TECNOCOAT system is complemented by a range of high-performance primers, including epoxy and polyurethane options, to ensure optimal adhesion and compatibility with various substrates.

For more information, visit polyglass.us.

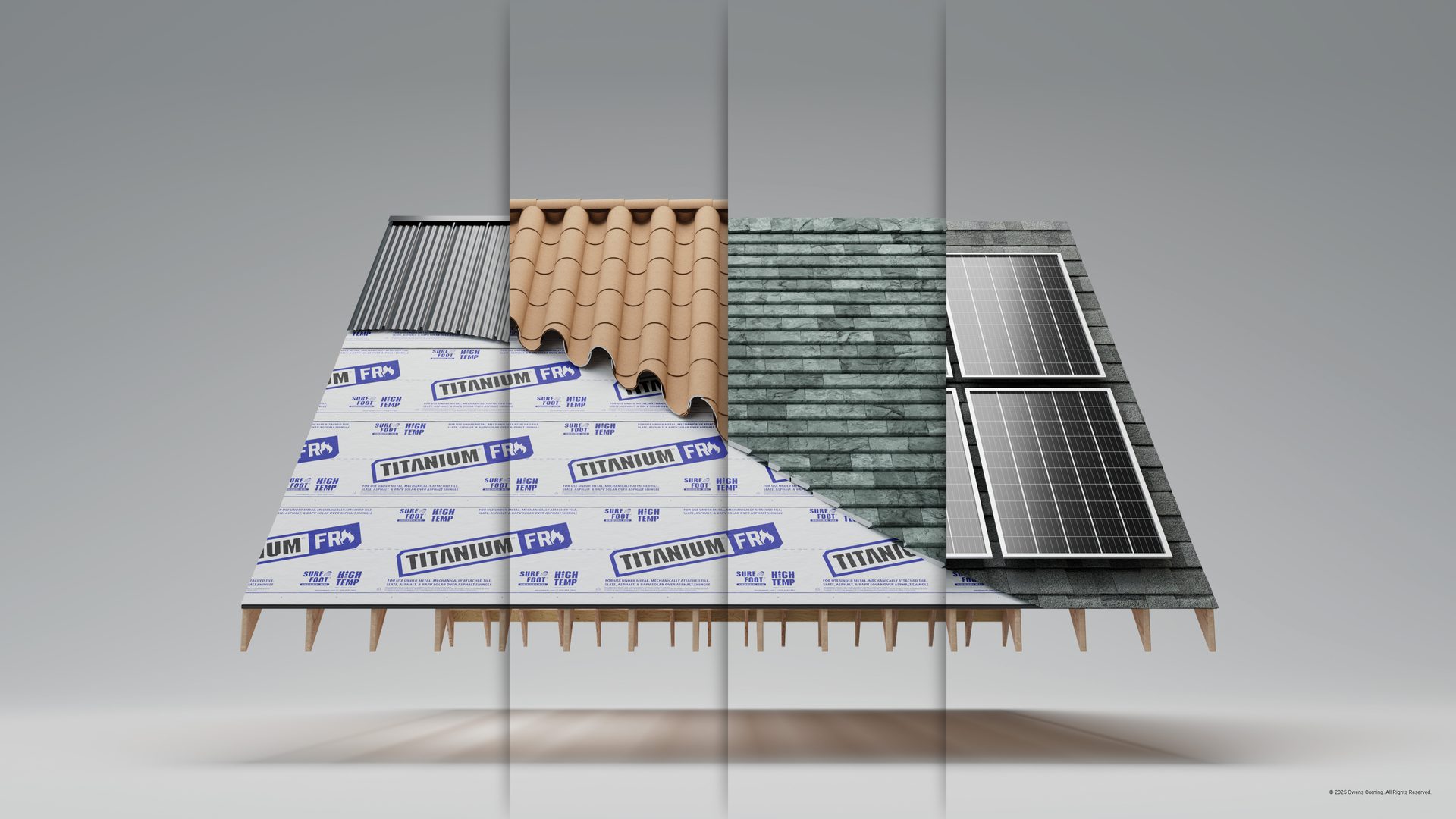

From wildfire zones to energy-generating roofs, Titanium FR high-temp self-adhered underlayment is designed to be a critical component of a roof assembly. With proprietary technology to help mitigate fire spread to the roof deck, Titanium FR meets Class A fire codes† and Wildland-Urban Interface (WUI) standards, and it can be used beneath BAPV solar panels. Plus, Titanium FR offers industry-leading benefits on the jobsite like improved walkability thanks to Sure-Foot technology, and easy repositioning.

†See installation instructions for specific Class A Fire Resistant roofing assemblies.

For more information, visit owenscorning.com.†See installation instructions for specific Class A Fire Resistant roofing assemblies.

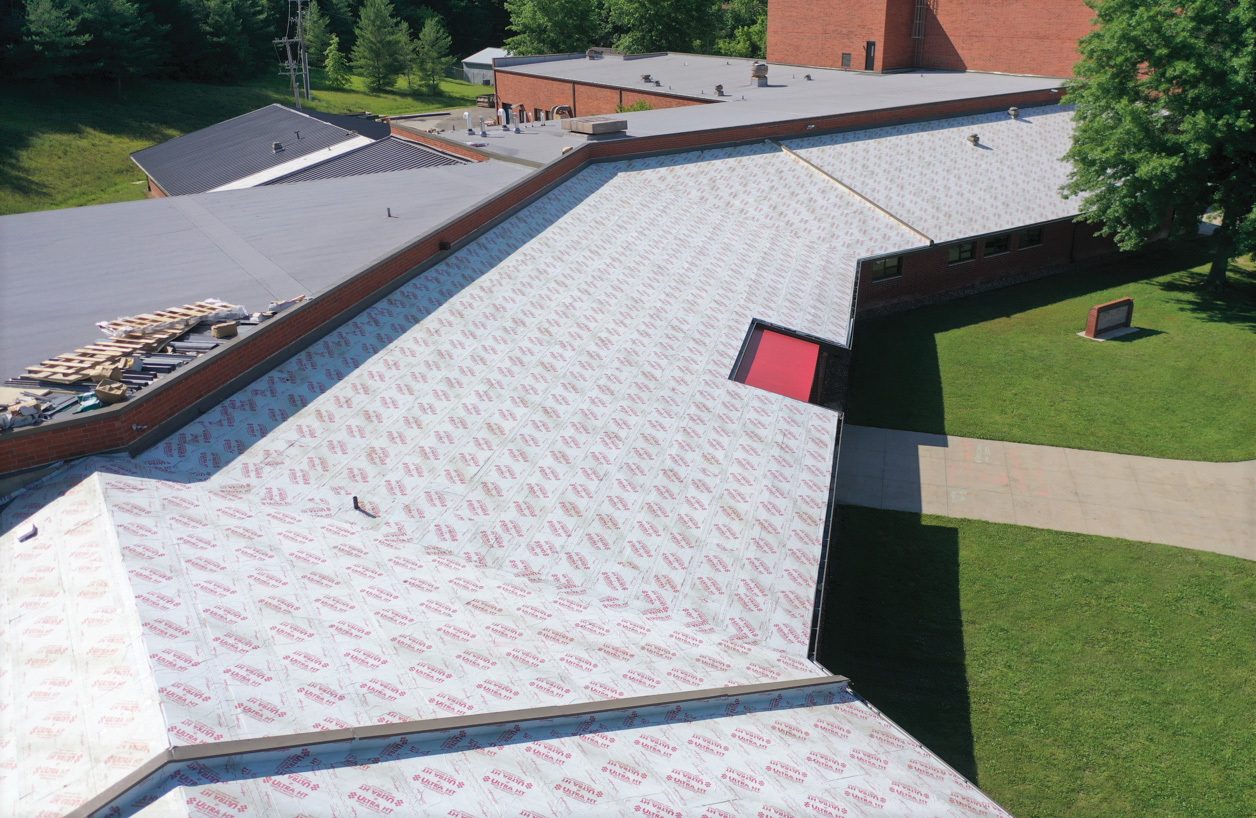

Ultra HT Wind & Water Seal is a high-temperature-rated self-adhering underlayment composed of a cross-laminated, non-slip polymer film laminated to a high-temperature rubberized asphalt adhesive rated to 250 degrees Fahrenheit. It is engineered for use with metal roofing systems where extreme heat is generated. Ultra HT is a Class A fire-rated membrane for use with 24 GA steel UL-classified roofing panels, as well as 3-tab Class A fire-rated shingles. This 45-mil underlayment is 36 inches x 67 feet and comes with a 10-year warranty.

For more information, visit mfmbp.com.

Image courtesy of Westlake Royal Roofing Solutions

The Elevate CLAD-GARD portfolio offers high-performance underlayment solutions for metal roofing systems. CLAD-GARD SA is a self-adhered, rubberized asphalt membrane with excellent flexibility, skid resistance and up to 239 degrees Fahrenheit heat resistance. CLAD-GARD R provides an economical, waterproof solution with a textured, walkable surface and a 60-day exposure rating. For steep slopes, CLAD-GARD MA is a mechanically attached, 100% recyclable synthetic underlayment that’s stronger and lighter than felt. All CLAD-GARD products are compatible with Elevate insulation systems and are eligible for Elevate Red Shield Warranties of up to 20 years.

For more information, visit holcimelevate.com.

IntelliWrap PR is a high-performance, self-adhered roofing underlayment designed to protect while allowing your roof assembly to breathe. It is both water- and airtight yet vapor permeable, helping to reduce trapped moisture. With a UV-stable, slip-resistant surface, it ensures safer walkability during installation. IntelliWrap PR is compatible with a wide range of roofing systems, including standing seam metal, slate, clay tile and cedar shingles, making it a versatile and durable choice for contractors and builders alike.

For more information, visit imetco.com.

The combination of QB2 + BoltSeal technology makes solar installation effortless on rolled asphalt, asphalt shingle, EPDM, and TPO, no matter the roof pitch. This game-changing mount is Intertek tested, UL Recognized and Miami-Dade Accepted — all without sealant, so you can feel confident knowing water intrusion will not affect the roof. All QuickBOLT products are manufacturer warrantied for 25 years, and QuickBOLT is the ‘Preferred Mounting Provider’ covered by SolarInsure’s 30-year parts and labor warranty. With more than 4 million units installed in 10 years — with zero reported leaks — QB2 is a no-brainer for installers.

For more information, visit quickbolt.com.

The white polyester top layer of Tarco’s LeakBarrier NR600 Ultra provides a lower-temperature working surface for the installer, while the thick layer of SBS compound self-seals around fasteners, preventing moisture penetration. The back side has an aggressive self-adhesive formulation that adheres to a variety of substrates. NR600 Ultra is an excellent choice for use under tile as well as under asphalt shingles, slate, and metal. The company says it is highly effective in critical roofing areas such as valleys, ridges, coping joints, chimneys, vents, dormers, skylights, and low-slope sections. The underlayment withstands temperatures up to 260 degrees Fahrenheit.

For more information, visit tarcoroofing.com.