Supplier's

Marketplace

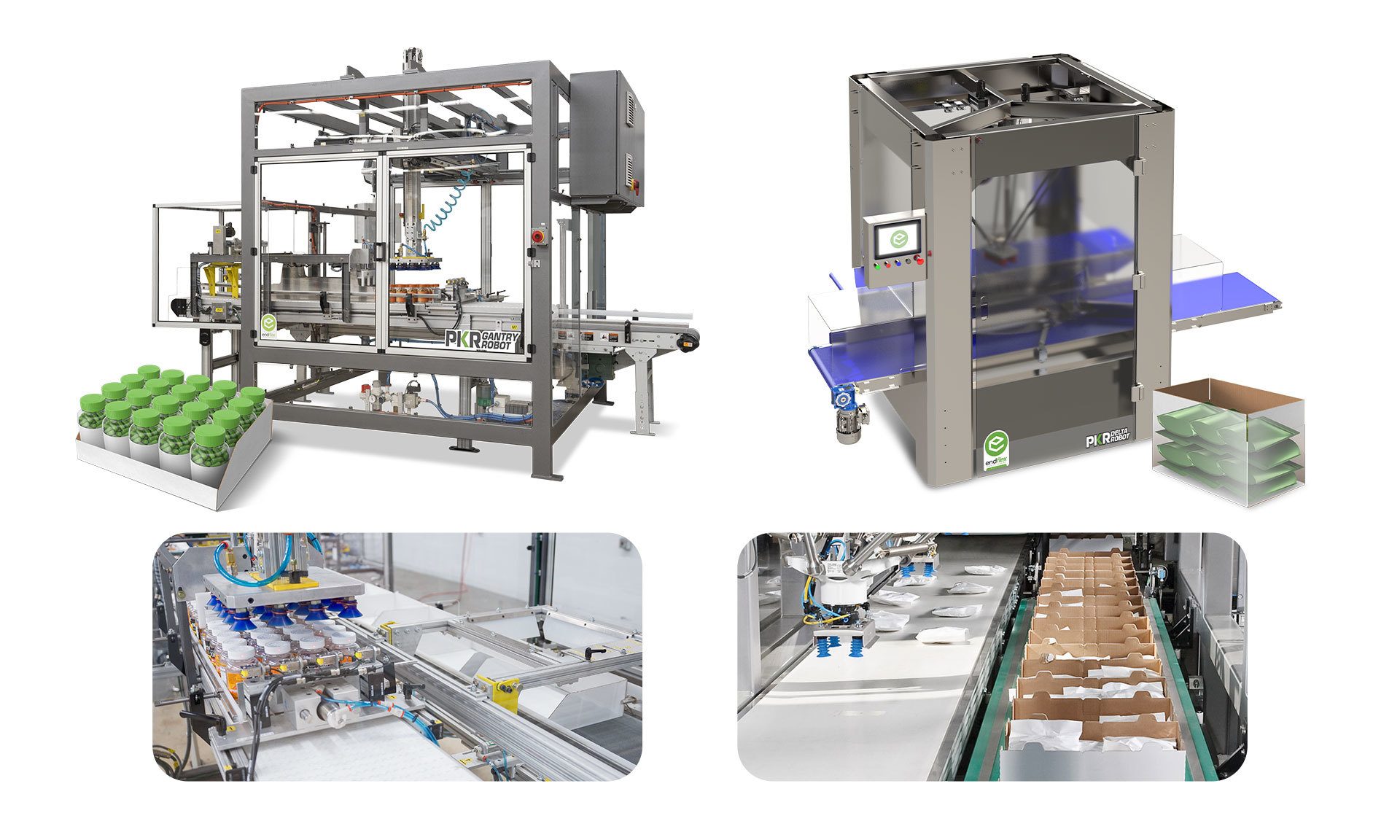

EndFlex engineers customizable robotic pick and place cells

The latest addition to EndFlex’s lineup of case and tray packing machines is the PKR modular pick and place cell with delta robot. The PKR Delta was designed as a packing solution for flexible bags and packages, the company says, and it accompanies other pick and place bots like the PKR Gantry, which is for packing rigid container products. Both rigid and flexible package-style products are accommodated with the flexibility of the top load case and tray packing machines. “Our clients needed faster, more compact and precise modular cells to compete in their respective industries,” said Jorge Perez, vice president of operations at EndFlex, in a statement. “They came to us with their wish lists and trusted us to find a solution. Our team of engineers and technicians got to work, and their efforts led to this new generation of robotic pick and place cells. The gantry and delta robotic cells we developed allow us to offer unique new solutions to some of the old packaging challenges.” The modular pick and place cells also can be customized to fit into existing production lines or integrated as part of complete packaging solution.

EndFlex LLC

4760 NW 128th St., Opa-Locka, Fla. 33054; 305/622-4070; endflex.com

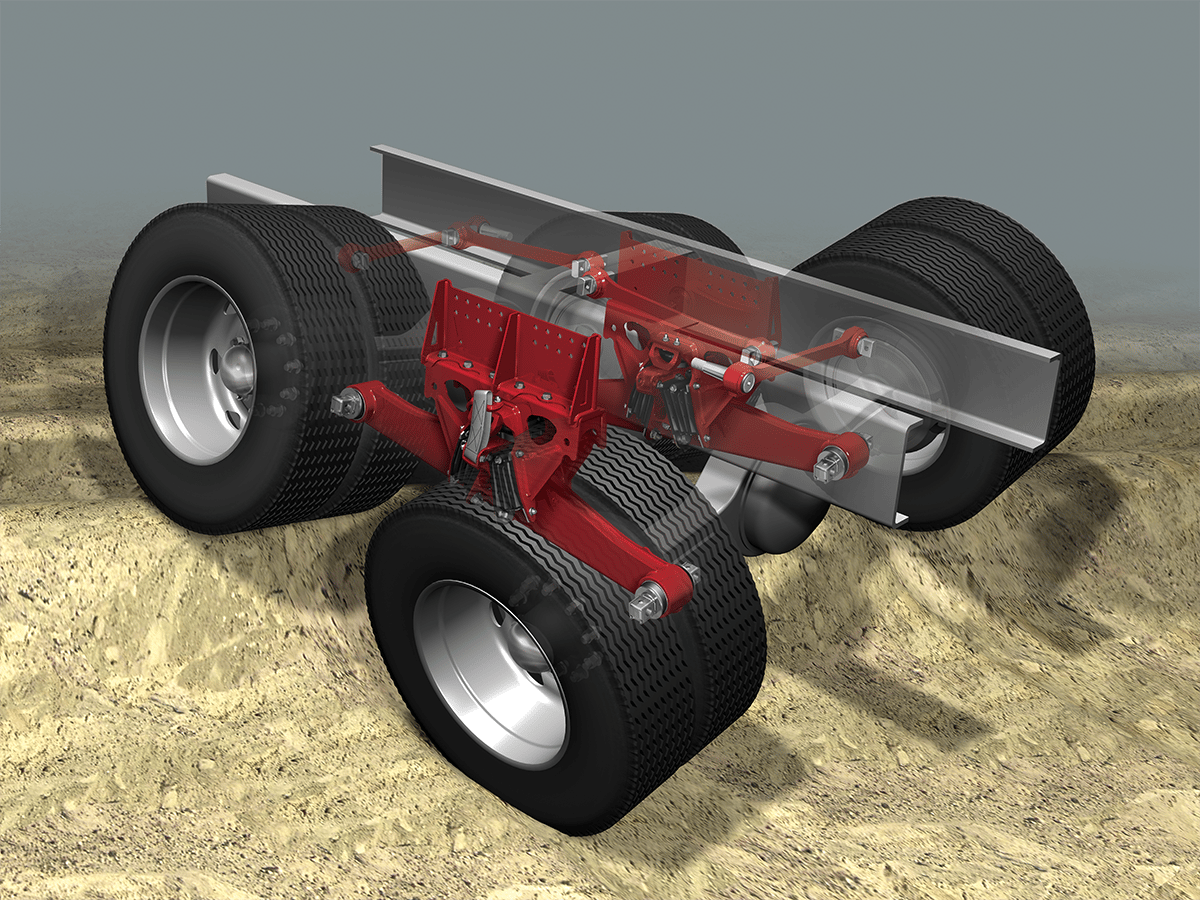

Hendrickson, Mack Trucks partner for HAULMAAX EX suspension

Hendrickson partnered with Mack Trucks to offer customers the Next Generation HAULMAAX EX, a heavy-duty rubber suspension system. The HAULMAAX EX suspension’s equalizing beam distributes the load equally between both axles in off-road and uneven terrain conditions and provides 17 inches of diagonal articulation, the company says. The system was designed to eliminate fixed center bushing points, reducing wheel hopping. With an integrate jounce stop, HAULMAAX EX protects from overloads, maximizing life for the progressive load springs and bolster springs. “HAULMAAX EX is extremely rugged, supporting demanding vocational applications and offering capacities of 40,000 pounds, 46,000 pounds and now 52,000 pounds, with up to 75,000-pound site rating,” said Ashley Dudding, director of engineering for Hendrickson, in a statement. “Hendrickson utilized our industry-leading analysis and validation techniques to ensure HAULMAAX EX would meet rigorous job-related demands, minimize maintenance requirements and deliver an advance, lightweight vocational suspension to the market.” Authorized Mack dealers now are selling the Mack TerraPro and LR cab-over vehicles with the HAULMAAX EX suspension. An increased tire clearance on the HAULMAAX EX suspension, which meets SAE standard for tire chain clearance, includes packages with 315 tires and 9-inch steel wheels.

Hendrickson Truck Commercial Vehicle Systems

800 S. Frontage Road, Woodridge, Ill. 60517; 630/910-2844; hendrickson-intl.com

New Delta robot from ABB fastest for lightweight product picking and packing

A five-axis Delta robot is the latest innovation in ABB’s FlexPicker portfolio. The IRB 365 has a 1.5 kg payload, making it both flexible and designed for reorienting packaged lightweight products, the company says. In response to the rise in eCommerce and a demand for shelf-ready packaged goods, the bot was developed for applications where production line speed and adaptability are essential, like food and beverages. “The IRB 365 can pick, reorient and place 1kg products at 120 picks per minute,” said Roy Fraser, global product manager for ABB Robotics, in a statement. “Our customers saw that the growth in online shopping was driving the demand for shelf-ready packaged goods, so we developed a new Delta robot that would rise to the challenge. By handling more products per minute, the IRB 365 robot increases productivity, while saving time and energy to make production more efficient.” The IRB is capable of many tasks, such as product reorienting, top-loading and secondary packaging, bottle handling, unscrambling and 3D picking. It’s powered by the Omnicore C30 controller, which is the smallest Delta robot controller on the market.

ABB Inc.

1250 Brown Road, Auburn Hills, Mich. 48326; 248/391-9000; new.abb.com

Carrier Transicold reveals sustainable trailer refrigeration units

In an effort to provide more sustainable options for transport refrigeration, Carrier Transicold released four premium performance trailer refrigeration units. The units offer double-digit fuel efficiency improvements and come with lifetime compliance with emissions requirements of the California Air Resources Board (CARB). These new systems include two single-temperature units and two multi-temperature units, all of which reduce particulate emissions by 96% and can improve fuel efficiency from 5-20%, Carrier Transicold says. “Whether interested in boosting fuel efficiency, seeking compliance with stricter emissions regulations or both, North America’s trucking fleets will soon have four new options,” said Steven McDonald, trailer product manager for Truck Trailer Americas at Carrier Transicold, in a statement. “The units will be available for order later this year for delivery in 2023, especially helping fleets operating in California that will be adding units next year and will be subject to CARB’s newly amended Airborne Toxic Control Measure for Transport Refrigeration Units.” The four new units also take advantage of a 24-horsepower smart engine that features clean engine technologies, provides a lifetime of regulatory compliance and achieves double-digit fuel economy, it says.

Versatile Vertical Blender from ROSS

Industrial mixing and blending equipment producer ROSS recently revealed the Vertical Blender. With a design that mixes reliably and gently, it can blend friable solids, abrasive materials and shear-sensitive products, the company says. This new blender consists of a low-speed auger that orbits the periphery of a conical vessel, while gently lifting material upward, it adds. Because of this motion, product from the top of the batch will mix with materials being drawn upwards by the auger. The steep angle of the blender provides efficient blending for batches as small as 10% of maximum capacity, as well as a speedy discharge of the material when it is finished blending. The company’s design, which requires no bearings or packing glands in the product zone, promotes 100% discharge and is easy to maintain while minimizing the risk of contamination, according to the company. ROSS says that both solid blends and wet applications routinely can be mixed in the blender. It can be jacketed for heating or cooling, making it a versatile machine. Heated materials within the Vertical Blender, when paired with vacuum conditions, can be quickly dried. The blender ranges in size, with models made for lab scale to full-production.

Carrier Transicold

700 Olympic Drive, Athens, Ga. 30601; 706/546-6469; carrier.com

Charles Ross & Son Co.

710 Old Willets Path, P.O. Box 12308, Hauppauge, N.Y. 11788; www.mixers.com

In July, polymer technology leader Aquapak Polymers partnered with Industrial Physics to design a harmonized set of water vapor transmission rate (WVTR) testing methods for its Hydropol biodegradable polymer. The hydropol is water soluble, completely biodegradable, non-toxic and UV resistant. Aquapak, like many others in the industry, struggled to establish a reliable and repeatable WVTR test method, it notes. With equipment from Industrial Physics, Aquapak will be able to provide its customers across a wide range of sectors with an alternative to traditional polymer, helping them cut plastic pollution in the process, it explains. In a statement, Aquapak’s quality control manager, Max Phippard, said Industrial Physics’ expertise was “critical to the success of this program.”

Maintenance, repair and operation replacement parts distributor Motion Industries Inc. recently promoted Lisa Solomon to senior vice president of corporate accounts. Having joined the company in 2015 as a business development manager, Solomon expanded her role and was promoted over the years, most recently working as area vice president of corporate accounts in 2021. As senior vice president, she will lead all of the company’s corporate accounts in North America, along with other groups. James Howe, executive vice president of eCommerce, sales excellence, strategic pricing and corporate accounts, noted that Solomon has “emerged has a peer leader” for the company’s AVPs across North America. “Her leadership and significant experience will further strengthen corporate accounts and maximize growth potential,” Howe said in a statement. “She is well-deserving of her new and expanded position.”

SOMIC Packaging, Eagan, Minn., hired Stacy Schmeiser as the new western regional sales manager. With 30 years of experience, he was originally trained in engineering and has lived in Arizona since 1997. He has an extensive background working in sales executive positions, most recently handling western regional sales for Syntegon. “I was looking for a dynamic company with superior technology and a strong reputation in the marketplace,” Schmeiser said in a statement. “After meeting with [SOMIC CEO] Peter Fox and the team in Minnesota and learning more about what they have to offer customers, I was convinced SOMIC was my future. My immediate goals are to develop a strong pipeline of projects and gain market share with some strategic wins.”

National farmer-owned dairy cooperative Dairy Farmers of America (DFA) named its new senior vice president of sustainability: Kevin O’Donnell. In his new role, O’Donnell is responsible for directing DFA’s sustainability activities and evolving the cooperative’s environmental, social and governance (ESG) efforts enterprise wide, the company notes. Prior to joining DFA, O’Donnell served as a sustainability strategy advisor at FTW Ventures, a venture fund that invests in sustainability-focused agriculture. “DFA and its farm families have a great sustainability story to tell, and I’m looking forward to helping write the next chapter,” he said in a statement. “Through customer partnerships, industry relationships and innovation, we have a lot of opportunity to advance our environmental stewardship on farms and in facilities.”

Encompass Technologies launched a set of three solutions designed to identify beverage manufacturers’ top brand-to-demand challenges that impact operational efficiencies and profitability. The comprehensive cloud-based platform for the beverage and food industries created these tools in an effort to enable beverage manufacturers to sell more by controlling brand presence, implementing better demand planning and supporting data-driven business decisions, it says. The three tools are Global Products, Distributor Ordering Portal and Distributor Reporting. “Beverage manufacturers need to modernize their business to grow successfully in a dynamic market,” said Jonathan O’Neil, CEO of Encompass, in a statement. “We’ve built the technology solutions that help them control brand and market presence, better plan and forecast, and make data-driven decisions to streamline operations.”