Trade News

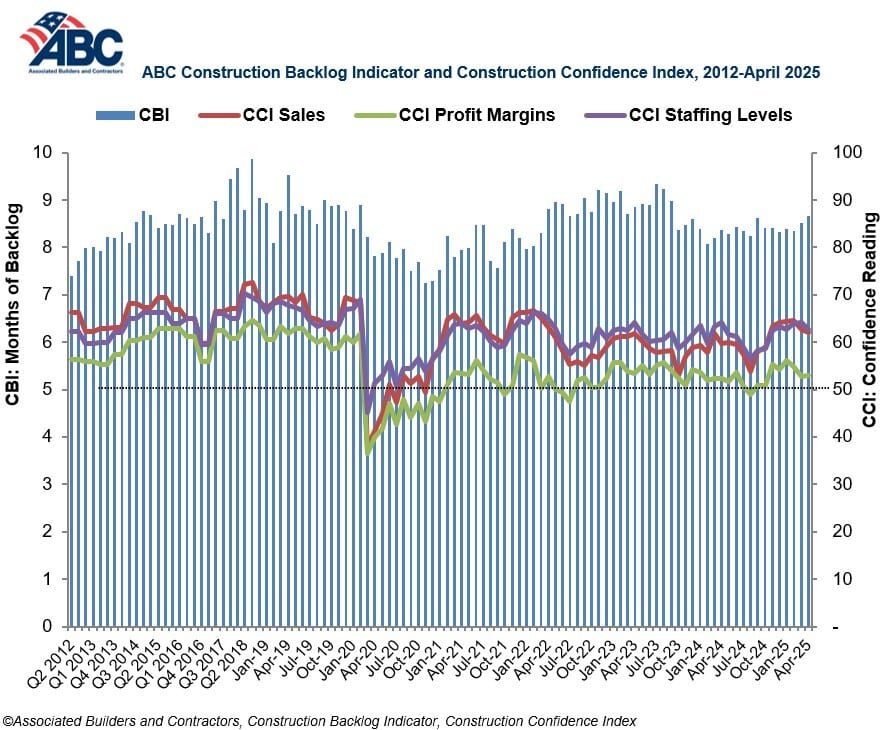

Contractors’ Expectations Improve in April, Reports ABC

Associated Builders and Contractors reported that its Construction Backlog Indicator rose to a 20-month high of 8.7 months in April, according to an ABC member survey conducted April 22 to May 6. The reading is up 0.3 months since April 2024.

View ABC’s Construction Backlog Indicator and Construction Confidence Index tables for April. View the full Construction Backlog Indicator and Construction Confidence Index data series.

Backlog has increased significantly over the past year for contractors with greater than $100 million in annual revenues. While backlog has also risen modestly for the smallest contractors, it is down on an annual basis for those with $30 million to $100 million in annual revenues.

ABC’s Construction Confidence Index reading for profit margins improved in April, while the readings for sales and staffing levels fell, though the outlook for sales is higher than a year ago. The readings for all three components remain above the threshold of 50, indicating expectations for growth over the next six months.

“Nearly 22 percent of contractors had a project delayed or canceled in April due to tariffs, up from 18 percent in March, while 87 percent have been notified of tariff-related materials prices increases,” said ABC Chief Economist Anirban Basu. “Contractors remain busy despite these headwinds; backlog rose in April and is now at the highest level since September 2023. While ABC members remain upbeat about the near-term outlook, the share of respondents that expect their sales to decline over the next six months rose to 19 percent in April, up 6 percentage points since the start of the year.”

Note: The reference months for the Construction Backlog Indicator and Construction Confidence Index data series were revised on May 12, 2020, to better reflect the survey period. CBI quantifies the previous month's work under contract based on the latest financials available, while CCI measures contractors' outlook for the next six months. View the methodology for both indicators.

LEED v5 Launch Sets New Standard—And EIFS is Ready to lead in Energy-Efficient Design

The U.S. Green Building Council has unveiled LEED v5, the latest evolution in sustainable building certification, emphasizing decarbonization and energy efficiency across a building’s full life cycle. LEED-certified buildings continue to deliver strong ROI—averaging 21 percent higher market sales prices and over 20% reductions in water, energy, and waste. With its superior insulation performance, EIFS is well-positioned to help architects and builders meet LEED v5’s aggressive efficiency and carbon reduction targets, in a release from EIMA’s EIFS Briefs newsletter.

Earlier this week, the U.S. Green Building Council launched the LEED v5 rating system for sustainable buildings. This is big news in the A/E/C space.

“Since its public launch 25 years ago, LEED has profoundly impacted millions of people in cities and communities around the world,” said Peter Templeton, president and CEO of USGBC. “LEED v5 raises the bar, further defining and evolving best practices and giving stakeholders across the building industry clear pathways to address today’s challenges to our health, climate and communities.”

Moreover, the release points out that LEED-certified assets are proven to drive return on investment and greater future earning potential. Notably, LEED buildings achieve a 21.4 percent higher average market sales price per square foot over non-LEED buildings; average 11 percent higher rent rates; attract more favorable and stable financing options; and reduce water, energy and waste by more than 20 percent. These environments also result in healthier and more productive employees and occupants. This version also goes beyond previous ones.

For example, decarbonization accounts for half of all points for LEED v5 certification to confront current climate needs. The new rating system provides clear, actionable steps to deliver ultra-low-carbon buildings by targeting emissions reductions across all aspects of the building lifecycle, including operations, embodied carbon, refrigerants and transportation. All LEED v5 projects will complete an operational carbon projection and will be given tools to craft a comprehensive, long-term decarbonization strategy, creating pathways for sustainable transformation.

PCA Changes Name to American Cement Association

Portland Cement Association, the national association representing U.S. cement manufacturers since 1916, announced it is changing its name to the American Cement Association. President and CEO Mike Ireland shared the news in Birmingham, Ala., during the 67th IEEE-IAS/PCA Cement Conference.

Nearly 1,200 cement industry professionals from around the world are attending the event this week, which is hailed as the cement and concrete industry’s premier annual conference. Following today’s announcement, the association will begin launching the new brand identity in June.

“The most important reason for the name change is that in recent years, U.S. cement manufacturers have expanded the types of materials they produce beyond Portland cement, working to develop more lower-emission cements in an effort to decarbonize the industry and increase domestic cement manufacturing capacity. The name ‘Portland Cement Association’ no longer accurately reflects the modern mindset of today’s manufacturers, or the materials they currently produce.” Ireland said.

Lower-emissions cement consumption has grown more than tenfold since 2021 and now accounts for more than 60 percent of total cement consumed in the U.S. In 2024, all 50 state Departments of Transportation approved the use of Portland/limestone cement. PLC reduces the carbon footprint of projects by up to 10 percent.

“Additionally, the rebranding makes it clear that we are a national association that speaks for cement manufacturers across the country,” Ireland said.

During the announcement, Monica Manolas, region president of Ash Grove Cement, and ACA Board Vice Chair, shared a video with conference attendees, revealing the association’s new slogan: Sustainable Cement for Resilient Concrete.

“The slogan summarizes the industry’s commitment to staying the course with our Roadmap to Carbon Neutrality,” Manolas said. “We continue to focus on developing new technologies and products to achieve not only net zero by 2050 but also to increase the capacity of American cement manufacturing to meet demand.”

MFM Building Products Brings on New Representation for Oklahoma

MFM Building Products announced that the firm has reached an agreement with Walco Building Products to represent MFM in Oklahoma.

Walco Building Products, led by President Kenny Kay, was founded in 1986 and serves architects, specifiers, roofing contractors, and building product distributors. The agency will represent MFM’s line of self-adhering waterproofing membranes with 1-Step and 2-Step distributors.

Milwaukee Reaches 100K Workers During Construction Safety Week in May

Each year, more than 150,000 construction workers are injured on the job in the U.S.—a sobering reminder that even as the industry navigates challenges like rising material costs and shifting trade policies, the protection of frontline workers must remain a top priority. Milwaukee Tool is taking bold steps to meet that challenge, investing more than $10 million annually in the trades. Among other things, this investment is being used to advance safety education, provide hands-on training, and create real-world solutions that reduce risk on the jobsite. During Construction Safety Week (May 5–9, 2025), that commitment came to life in powerful ways.

In just five days, 385+ Milwaukee Tool employees led safety-focused efforts in partnership with jobsites, unions, and training centers across the country. The result:

- 635+ safety training sessions conducted

- 100,000+ workers reached through hands-on demonstrations and expert-led instruction

- 850+ hours of training provided throughout the U.S.

From engineering personal protective equipment (PPE) that increases comfort and compliance, to designing tools that reduce fatigue and repetitive stress injuries, Milwaukee Tool continues to build safety into every corner of the jobsite.

“Our mission is simple: empower the men and women who build our nation with the knowledge and equipment to do their jobs safely,” said Scott Teson, senior vice president of Sales for Milwaukee Tool. “During Construction Safety Week and every week, we’re proud to partner with the trades to turn that mission into measurable impact.”

“The compromise and preparedness leading up to Safety Week are unmatched,” said Jason Garcia, safety manager for Turner Construction in Houston. “[Milwaukee Tool’s] consistent interaction with the team and trade partners on site, not only during construction week but throughout the year, is exceptional.”

Milwaukee Tool has a bold goal of investing a total of $200 million in the skilled trades by 2030–continuing its unwavering support for the future of the industry. Milwaukee Tool’s long-standing commitment to union and non-union trade organizations, apprenticeship programs, and workforce development initiatives has helped attract thousands of men and women across the U.S. into the skilled trades.

Enter Now for W&C Top 50 Contractors

Walls & Ceilings magazine is revisiting its competition W&C Top 50 Contractors. This feature charts North America’s best wall and ceiling contractors.

Contractors are now encouraged to visit wconline.com/WC-Top-50, and fill out the online questionnaire. For the “Company History” category, be sure to tell us about your company in 200 words or more.

Spackle by Dave Coverly

People News

Knight Wall Systems today announced the hire of Noé Martínez as project manager, according to Knight Director of Sales, Engineering & Marketing Brian Nelson.